Principles of copper alloy smelting process:

1. The surface of all metal charge materials should be cleaned and preheated. At the same time, we should roast or pre-melt the flux to completely remove moisture. When changing the alloy grades, pay special attention to the fact that tin bronze, lead bronze, and nickel bronze cannot be smelted on the used furnace lining of aluminum bronze, aluminum brass, and silicon brass.

2. The copper alloy liquid is easy to oxidize and get gas. It should follow the principle of “fast smelting and timely pouring”. In other words, the copper liquid does not stay in the furnace for too long.

3. The controlled furnace atmosphere is neutral, and tin bronze and lead bronze can be smelted in a weakly oxidizing furnace atmosphere.

4. The order of feeding is very important, and the principle of “rapid melting, prevention of oxidation, and air absorption” should be obeyed. The specific order should be used flexibly according to the composition of the charge and the characteristics of the smelting equipment.

5. The smelting temperature is closely related to the quality of the copper liquid and should be strictly controlled to meet the process requirements.

6. Carry out the quality inspection before the furnace in time and accurately.

Safety measures for copper alloy smelting process:

1. The operator should wear protective equipment, and the work site should be kept tidy and free of water and debris.

2. check whether the equipment used is intact before starting the furnace, and remove any unsafe factors in time.

3. It should be carefully checked and confirmed that there are no explosive and dangerous substances in the charge before it can be preheated.

4. smelting casting tools, such as stirring rods, iron spoons, slag removal tools, etc. shall not be in contact with the alloy liquid.

5. The remaining alloy liquid during pouring should be poured into the preheated ingot mold and poured on the ground or poured back into the furnace.

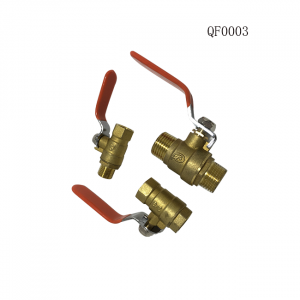

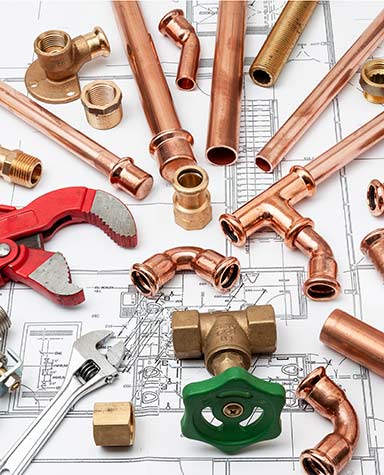

brass cast pipe