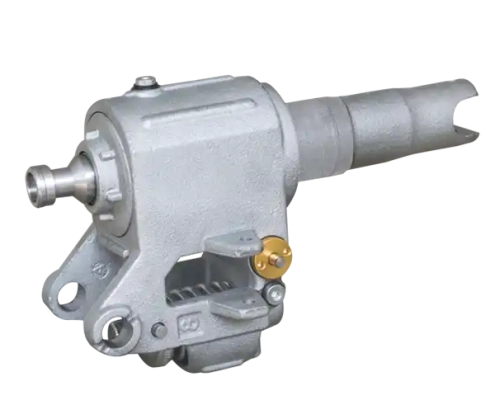

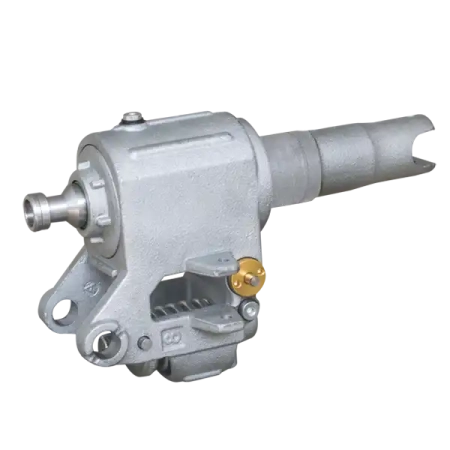

What is brass casting?

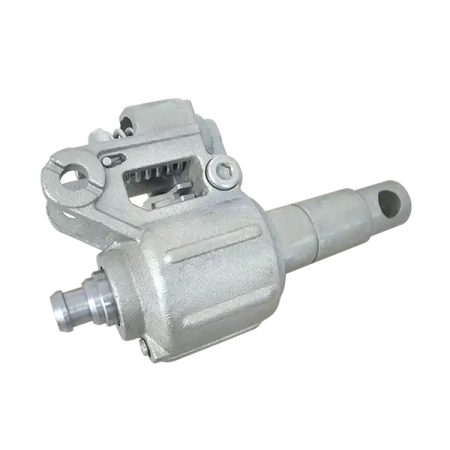

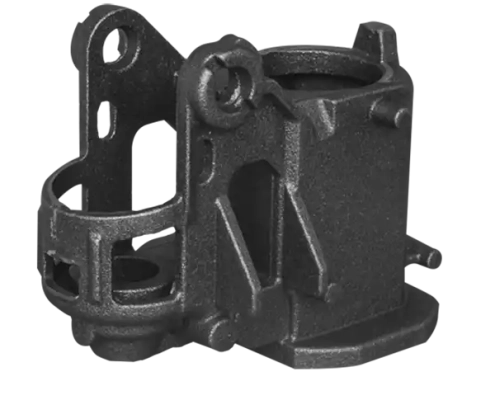

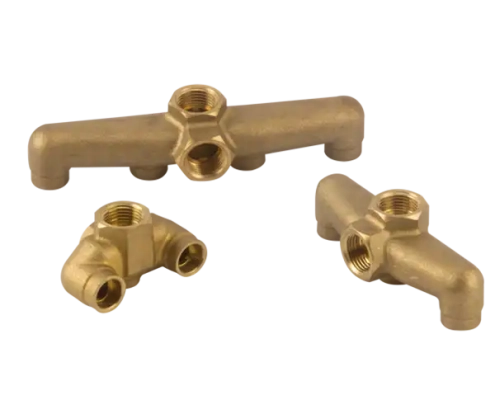

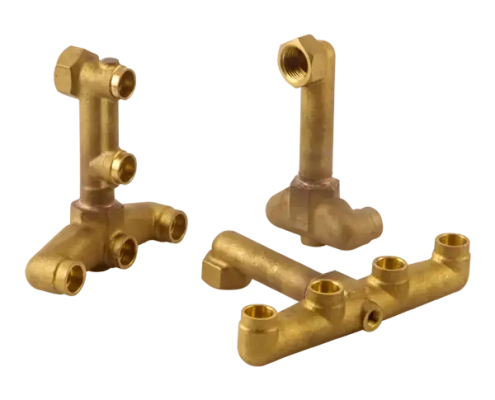

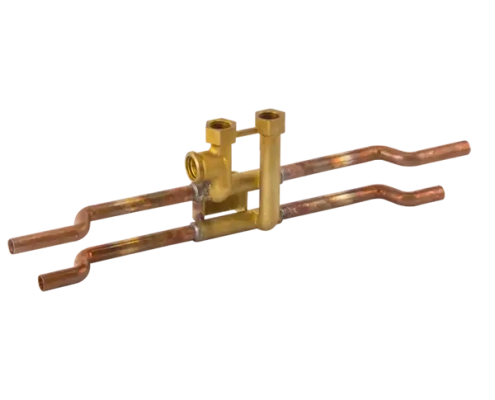

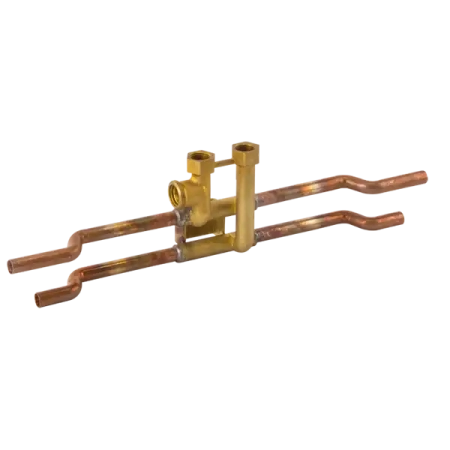

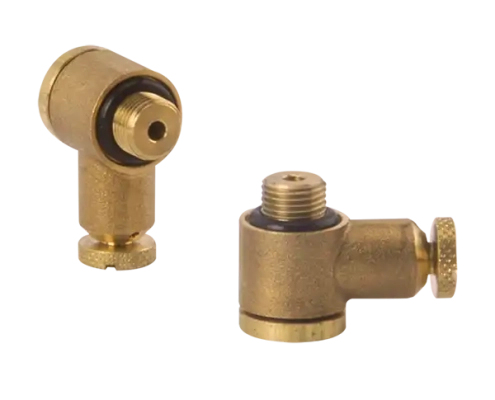

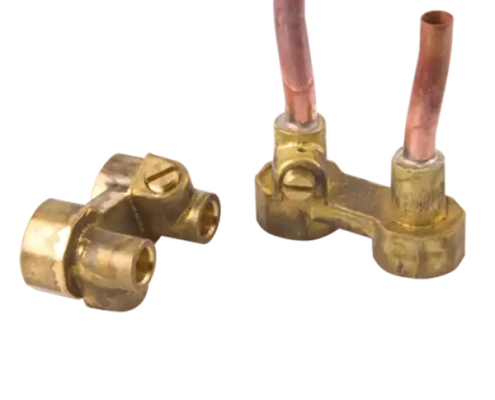

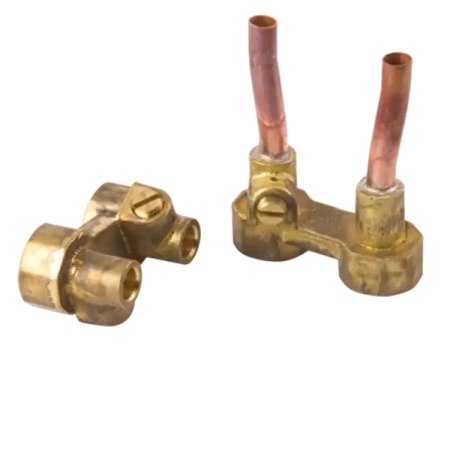

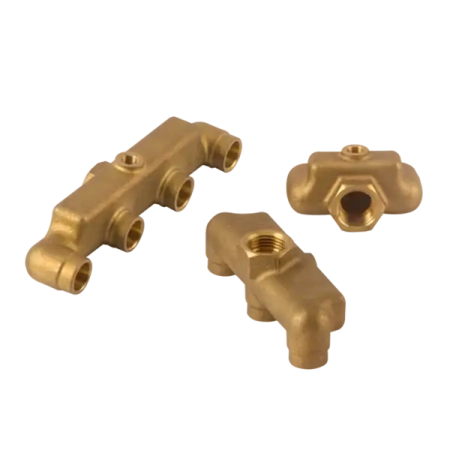

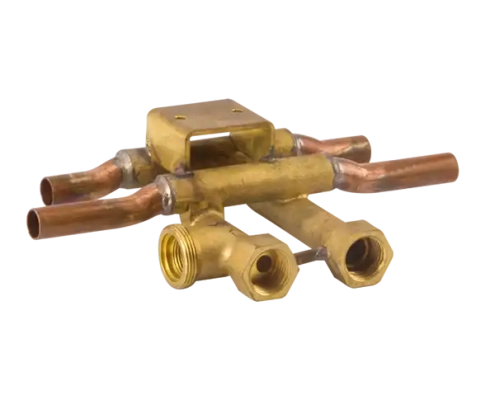

Brass casting is a manufacturing process in which molten brass after a high temperature is poured into a mold and allowed to solidify into a desired shape. The model is made of a variety of materials, including clay, plaster, or even sand. The final brass casting parts have a relatively more smooth surface finish than iron casting. The benefit of brass casting is that it is relatively inexpensive compared to other manufacturing methods. This makes it a cost-effective option for producing large quantities of items, such as door handles or plumbing fixtures.

What is brass casting used for?

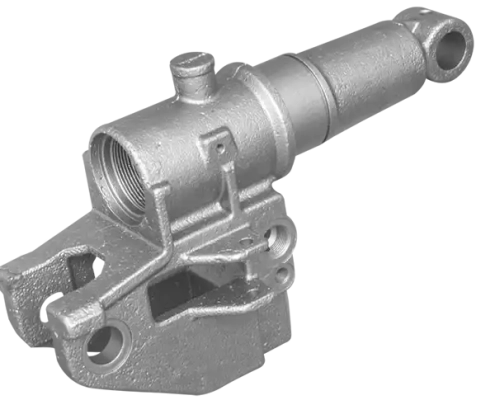

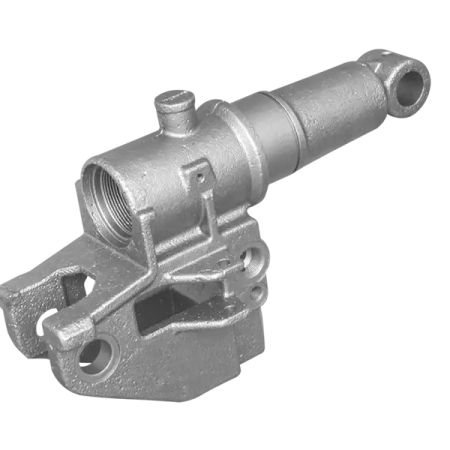

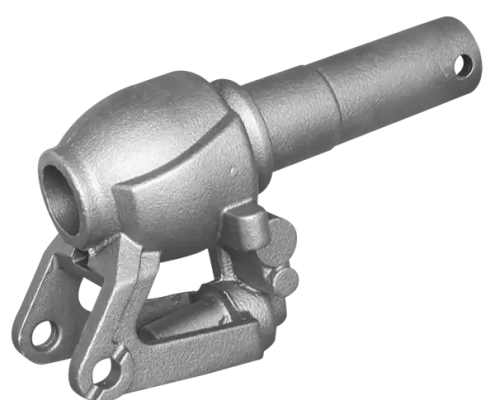

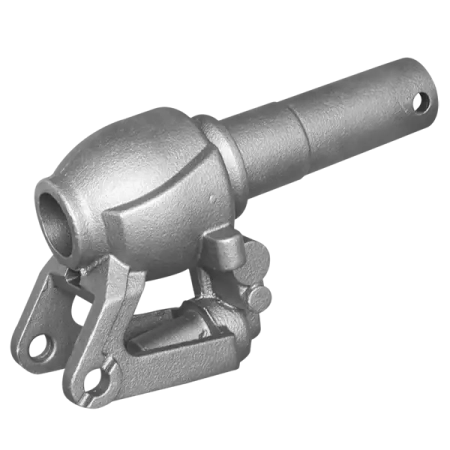

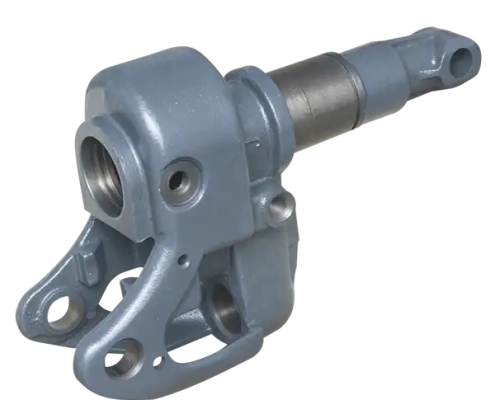

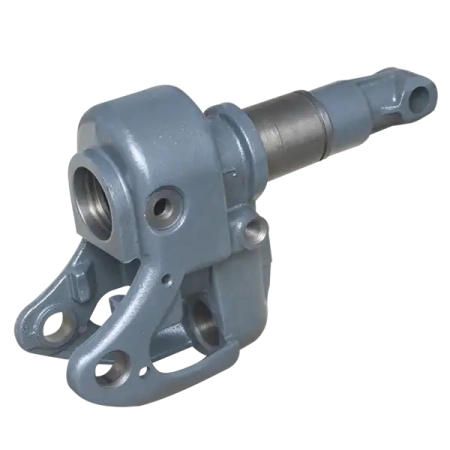

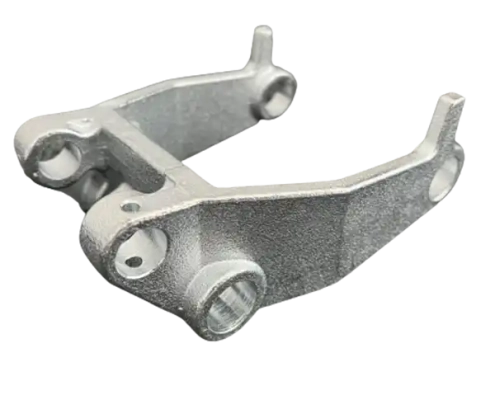

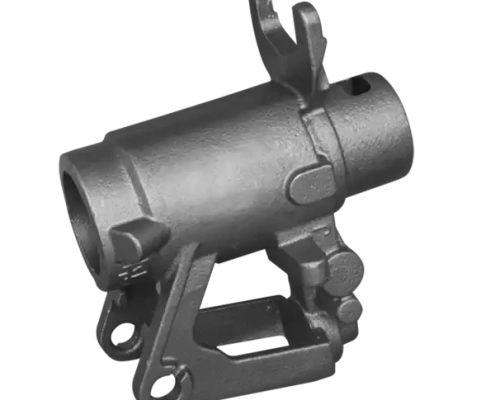

Brass casting is a versatile manufacturing process that can be used to create a wide range of products in various industries with high precision and accuracy. Therefore, brass casting parts can be used in architectural hardware, plumbing fixtures, automotive and aerospace, musical instruments, art, sculpture, jewelry, electrical and electronic components, and home decor. Faucets, valves, door handles, knobs, locks, gears, bushings, bearings, connectors, switches, circuit breakers, etc brass parts are suitable for made of brass casting.

How to make customized sand casting parts from us?

Firstly, we often ask for drawing files of brass casting that include all necessary dimensions, materials, and features. Then we will produce the brass part sample and send it to you for testing and improvement until the cast parts are in line with your requirements. Next, we can arrange the big production after the deposit.

Click for More brass casting parts.