JM Heat Exchanger for Air Conditioner

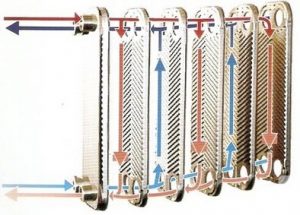

As a cast iron supplier with decades years experience, Yide Casting always provides patented brass heat exchangers for our customers. Casting heat exchangers are a key component of air conditioners, as they are responsible for conducting the heat transfer between the air and the coolant. Heat exchangers typically consist of a series of metal plates or tubes, sometimes called fins, with spaces between them that allow air to pass through. These fins connect to each other and to central ductwork in order to create an efficient system for exchanging heat. Heat exchangers also serve to reduce noise levels and vibration, ensuring a quieter operation and improved energy efficiency.