Our Blog

Yide Casting shows some iron casting, brass casting knowledge, and our company news here. We hope to provide a little help to someone that needed it.

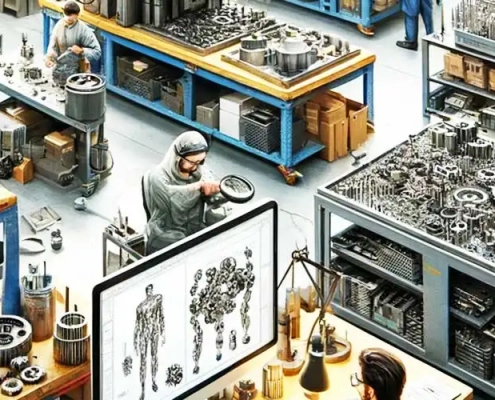

https://www.yidecasting.com/wp-content/uploads/2023/11/What-are-the-advantages-of-choosing-customized-casting-parts-over-standard-ones.webp

500

1200

Yide Casting

http://www.yidecasting.com/wp-content/uploads/2020/05/YiDe-iron-casting-manufacturer-logo-300x137.png

Yide Casting2023-11-12 12:13:242024-05-20 14:07:51What are the advantages of choosing customized casting parts over standard ones?

https://www.yidecasting.com/wp-content/uploads/2023/11/What-are-the-advantages-of-choosing-customized-casting-parts-over-standard-ones.webp

500

1200

Yide Casting

http://www.yidecasting.com/wp-content/uploads/2020/05/YiDe-iron-casting-manufacturer-logo-300x137.png

Yide Casting2023-11-12 12:13:242024-05-20 14:07:51What are the advantages of choosing customized casting parts over standard ones?

Navigating the Nuances of Eco-Conscious Customized Iron Casting Part Design

/

0 Comments

Navigating the Nuances of Eco-Conscious Customized Iron Casting…

What are the key considerations when selecting an iron casting service provider for aerospace OEM parts?

Know About Aerospace OEM Parts and Iron Casting

The aerospace…

https://www.yidecasting.com/wp-content/uploads/2023/10/The-Difference-Between-Ductile-Iron-Casting-and-Gray-Iron-Casting.webp

450

1200

Yide Casting

http://www.yidecasting.com/wp-content/uploads/2020/05/YiDe-iron-casting-manufacturer-logo-300x137.png

Yide Casting2023-10-23 12:22:292024-05-20 13:33:02The Difference Between Ductile Iron Casting and Gray Iron Casting

https://www.yidecasting.com/wp-content/uploads/2023/10/The-Difference-Between-Ductile-Iron-Casting-and-Gray-Iron-Casting.webp

450

1200

Yide Casting

http://www.yidecasting.com/wp-content/uploads/2020/05/YiDe-iron-casting-manufacturer-logo-300x137.png

Yide Casting2023-10-23 12:22:292024-05-20 13:33:02The Difference Between Ductile Iron Casting and Gray Iron Casting

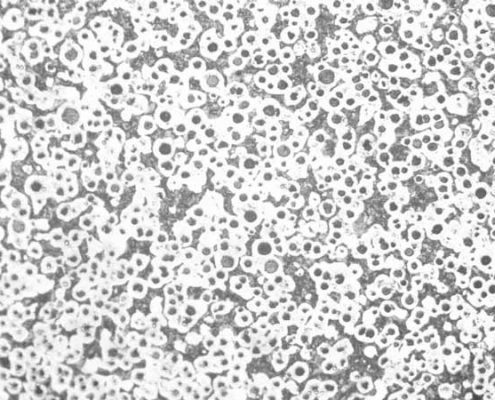

Cast Iron Shrinkage Defects

Cast iron shrinkage defect has a great influence on the quality…

Manuel Hidrolik Palet Krikosu Bakımı ve Genel Arızaları

Manuel Hidrolik Palet Krikosu Bakımı ve Genel Arızaları

Bugün…

Advantages and Disadvantages of Stainless Steel Casting Process

Advantages and disadvantages of stainless steel casting process

Everyone…

https://www.yidecasting.com/wp-content/uploads/2020/05/bronze-casting-brass-casting-pipe.jpg

475

384

Yide Casting

http://www.yidecasting.com/wp-content/uploads/2020/05/YiDe-iron-casting-manufacturer-logo-300x137.png

Yide Casting2021-12-30 02:33:022023-06-16 02:49:13The Smelting Process of Copper Alloy

https://www.yidecasting.com/wp-content/uploads/2020/05/bronze-casting-brass-casting-pipe.jpg

475

384

Yide Casting

http://www.yidecasting.com/wp-content/uploads/2020/05/YiDe-iron-casting-manufacturer-logo-300x137.png

Yide Casting2021-12-30 02:33:022023-06-16 02:49:13The Smelting Process of Copper Alloy

The Density of Ductile Iron

The density of ductile cast iron is approximately 7.3 g/cm3,…