In our daily lives, there are many products related to cast iron and cast steel. It can be said that the products of these two materials are ubiquitous in life. However, many friends still have some hesitation when buying products composed of cast iron or cast steel. Do they want to know what is the difference between the two? Which is better? Today, let us have a detailed understanding.

The essential difference between cast iron and cast steel:

It is understood that the main difference between cast iron and iron steel is the difference in carbon content, which directly affects the strength and plasticity.

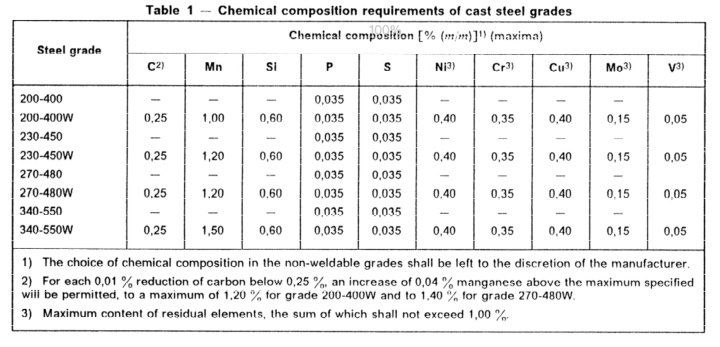

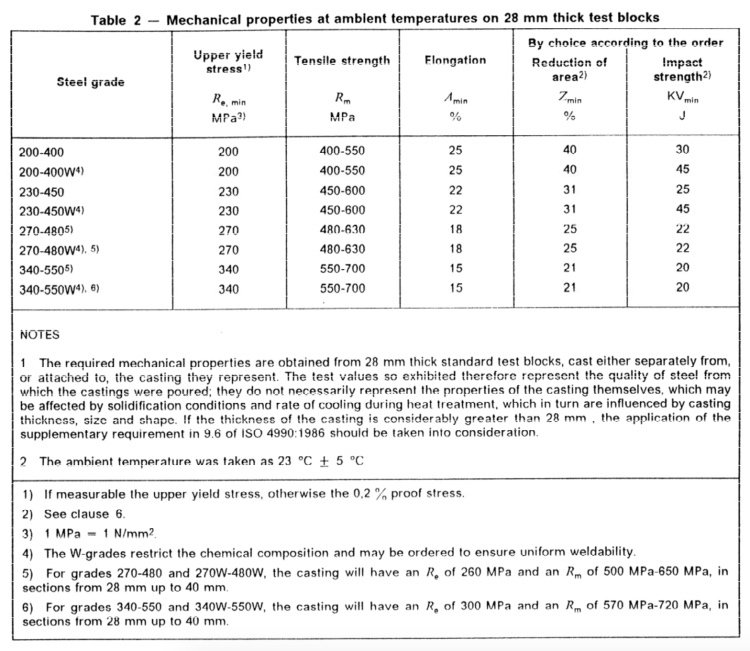

Cast steel is also called carbon steel. It is an iron-carbon alloy of less than 2% carbon content . In addition to carbon, carbon steel generally contains a small amount of silicon, manganese, sulfur and phosphorus. Carbon steel can be divided into three types: carbon structural steel, carbon tool steel and free-cutting structural steel according to its purpose. Carbon structural steel is divided into building structural steel and machine-made structural steel.

According to the carbon content, carbon steel can be divided into low carbon steel (WC ≤ 0.25%), medium carbon steel (WC0.25%-0.6%) and high carbon steel (WC>0.6%). According to phosphorus and sulfur content, carbon steel can be divided into ordinary carbon steel (high phosphorus and sulfur), carbon steel (low phosphorus and low sulfur) and high-grade steel (lower phosphorus and sulfur). Generally, the higher the carbon content of carbon steel, the higher the hardness and strength, but the lower the plasticity.

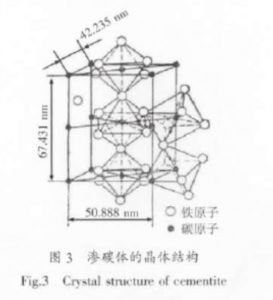

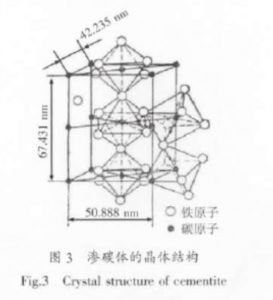

Cast iron is an iron-carbon alloy of more than 2% carbon content. Industrial cast iron generally contains 2% to 4% carbon. Carbon is mostly present in the form of graphite in cast iron, and sometimes in the form of cementite. In addition to carbon, cast iron also contains 1% to 3% silicon, as well as elements such as manganese, phosphorus, and sulfur. Alloy cast iron also contains elements such as nickel, chromium, molybdenum, aluminum, copper, boron, and vanadium. Carbon and silicon are the main elements that affect the microstructure and properties of cast iron.

The differences in properties of cast iron and cast steel:

1. The brightness is different

The brightness ratio of steel castings is very large, while that of iron castings is gray. And among cast iron, the brightness of gray iron is darker than that of ductile iron.

2. The particle is different

Regardless of whether the cast iron is ductile iron or gray iron, particles can be seen with naked eye, and the particles of gray iron are larger. While precision steel castings have high density and no particles on the surface can be seen with the naked eye.

3. The sound is different

The sound of iron castings is relatively crisp.While the impact of steel castings will produce the sound of “gang gang”.

4. The gas cutting is different

The surface of steel castings is relatively rough, with large riser and gate area, which must be treated by gas cutting. However, gas cutting is useless on cast iron.

5. The toughness is different

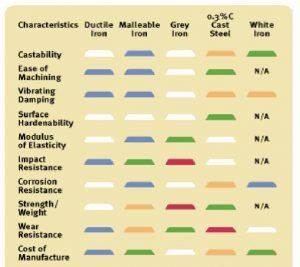

The toughness of cast iron is slightly poor, and gray iron even has no toughness. While the toughness of precision steel castings is similar to that of steel plates, and better than cast iron.

Last but not least, let us find out which is better, cast iron or cast steel?

Whether cast iron is better or cast steel is better, you must first confirm what you want to do with. Cast steel has less carbon content and good toughness. Therefore, steel has a wider range of uses than pig iron. Steel not only has good plasticity, but also steel products have high strength. Generally speaking, mechanical properties such as elongation are better than cast iron.

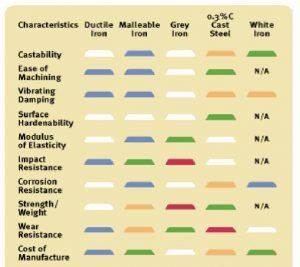

Ductile cast iron is a high-strength cast iron material appeared in the 1950s. Its comprehensive performance is close to that of steel. It is precisely based on its excellent performance, ductile cast iron has been successfully used to cast parts with complex forces and high requirements for strength, toughness and wear resistance. Ductile cast iron has rapidly developed into a cast iron material second only to gray cast iron. In addition, the corrosion resistance and oxidation resistance of ductile cast iron exceed those of cast steel. The so-called “substituting iron for steel” mainly refers to ductile iron.

Yide casting is a leading casting foundry in China, with 27 years’ experience, produces top quantity cast iron and cast steel products. If you are interested in our casting fitting, please send us a drawing file, and feel free to get a quite quote.