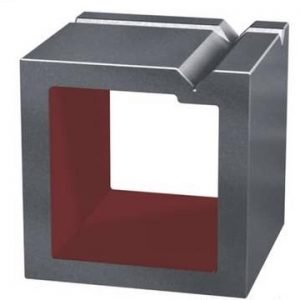

A cast iron block is a cast iron piece with a block shape (for example, cubic, rectangular, spherical). Most cast iron blocks are used as counterweights or weighing hammers.

Based on the application, most cast iron blocks have no requirements for materials, such as cast iron grades. However, for the cast iron blocks used in tractors, forklifts, trucks and elevators and other machinery and equipment, some buyers will require the material to be gray cast iron ASTM NO.30, FC200, GG20. This ensures that the casting has a certain strength. While working at Yide Casting, I rarely heard of cast iron blocks made of ductile iron.

The size, flatness and parallelism of the cast iron block are very important for the adaptability to other parts. But generally should accept the flat rough surface after grinding. And no mechanical processing is required except for special requirements.

The most important issue of cast iron blocks is price. The price must be very low because of their low requirements and good unit weight. Most iron foundries in China can produce such castings. Therefore, for small cast iron blocks, try to produce them through the green sand floor molding process. But for large cast iron blocks, resin sand casting process must be carried out. Although the price of resin sand castings has been greatly increased due to the increase in resin prices, this process can ensure good surface quality, flatness and parallelism of large cast iron blocks.

As a leading casting foundry in China, we pursue manufacturing quality durable iron casting and best machining service for our customers, we also have a professional stainless steel casting cooperator to finish the best casting order, and do the best work of casting parts, and finish the casting iron parts or steel casting products in best quality, whether you are looking for stainless steel casting foundry or iron casting foundry or machining casting manufacturer, please feel free to contact us, we’d like to serve you, and provide you best casting service.