Know About Aerospace OEM Parts and Iron Casting

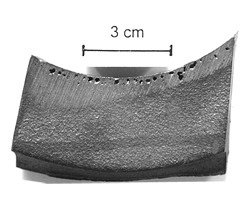

The aerospace industry is synonymous with precision and innovation, a domain where every component, no matter how small, is crucial to the overall functionality and safety of the aircraft. Iron casting plays a pivotal role in producing these OEM parts, offering the durability and strength required for the demanding conditions of flight. Selecting the right iron casting service provider is a decision that can significantly influence the quality and reliability of these vital components.

Understanding the Aerospace OEM Landscape

Aerospace OEM parts vary from the smallest fasteners to large fuselage components, all requiring the same attention to detail during their creation. Iron casting for aerospace applications is not just about pouring molten metal into a mold; it involves a meticulous process of design, material selection, and finishing that adheres to the strict specifications set by aerospace authorities.

The Role of Customized Iron Casting in Aerospace

Customized iron casting is at the forefront of aerospace component manufacturing. Service providers that can deliver personalized casting solutions enable OEMs to achieve the bespoke designs necessary for unique aerospace applications. This customization is not limited to shape and size but also extends to the material properties, where different iron alloys are selected to match the specific performance requirements of each part.

The Importance of Material Quality in Iron Castings

Selecting the Right Iron Alloy

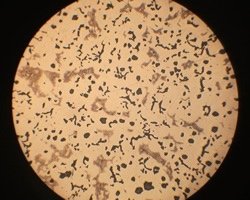

The quality of the material used in iron castings directly impacts the performance and longevity of aerospace OEM parts. Providers must offer a variety of iron alloys, such as gray iron, ductile iron, or malleable iron, each with its own set of characteristics that make it suitable for different aerospace applications.

Ensuring Durability and Performance

In the context of aerospace, durability and performance are non-negotiable. The iron casting process must ensure that the final product can withstand extreme temperatures, pressure changes, and mechanical stress. This is where the expertise of the service provider in material science becomes invaluable, as they must be able to guarantee that the material quality meets or exceeds industry standards.

Precision and Accuracy Requirements for Aerospace Components

The aerospace industry is unforgiving when it comes to the precision and accuracy of its components. Iron casting for aerospace OEM parts is a high-stakes game where even the slightest deviation from the required specifications can have significant consequences.

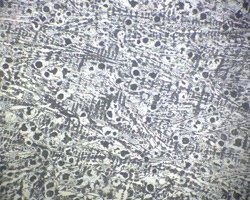

Engineering to Exacting Tolerances

Engineering iron castings for aerospace applications means adhering to exacting tolerances that can be as minute as a few micrometers. Such precision ensures that each component fits flawlessly within the complex assemblies of an aircraft, maintaining the integrity and functionality of the machine.

Customized Casting for Perfect Component Fit

The ability to customize iron castings is essential for achieving the perfect fit. It involves precise control over every stage of the casting process, from initial mold design to the final machining of the cast part. Providers must utilize advanced technologies such as 3D printing for molds and CNC machining to achieve the level of accuracy that aerospace components demand.

Certifications and Standards Compliance

Iron casting for aerospace OEM parts is heavily regulated, and compliance with international standards and certifications is not optional. These certifications are indicators of a provider’s ability to produce components that are safe, reliable, and of high quality.

Adhering to Aerospace Quality Management Systems

Compliance with quality management systems like ISO 9001 and the aerospace-specific AS9100 standard is essential. These standards ensure that the provider has a systematic approach to managing quality and that they can consistently meet customer and regulatory requirements.

The Importance of NADCAP Accreditation

For certain processes such as welding, chemical processing, and non-destructive testing, NADCAP accreditation becomes relevant. It is a specialized certification that shows a provider’s commitment to meeting the stringent standards of the aerospace industry, particularly in the specialized processes that are critical to the integrity of aerospace components.

Experience with Aerospace OEM Part Production

A track record of experience in the aerospace industry is a significant factor when selecting an iron casting service provider. It speaks to the provider’s understanding of the unique challenges and requirements of the industry.

Proven Expertise in Aerospace Component Manufacturing

Providers with a history of producing aerospace components bring a depth of expertise and an established reputation. They are likely to have a more nuanced understanding of the aerospace sector’s needs and the challenges that come with meeting those needs.

Leveraging Past Successes for Future Innovations

A service provider’s past successes can be a harbinger of future performance. Those who have successfully navigated complex aerospace projects are better equipped to innovate and adapt to the evolving demands of the industry.

Technological Capabilities for Complex Castings

In the field of aerospace OEM parts manufacturing, leveraging the latest technological advancements is not just advantageous—it’s imperative. Service providers must be at the cutting edge of iron casting technology to deliver components that push the boundaries of what’s possible.

Advanced Technologies for Enhanced Precision

The use of advanced technologies in the casting process is a game-changer. Techniques such as 3D printing for sand molds, precision simulation, and digital modeling contribute to achieving enhanced precision in iron castings. These technologies allow for the creation of components with complex geometries and internal features that were once considered impractical, if not impossible.

Customized Solutions with High-Tech Machining

High-tech machining capabilities allow for customized solutions that meet the unique demands of aerospace OEM parts. The ability to machine intricate details post-casting is crucial, and providers must have the equipment and expertise to carry out such precision work, often on a customized, case-by-case basis.

Lead Time and Flexibility in Production

The aerospace industry operates within tight deadlines, and the ability to deliver high-quality castings quickly is a significant competitive advantage for an iron casting service provider.

Streamlining Production for Rapid Turnaround

A streamlined production process is essential for meeting the demanding lead times of aerospace OEM parts. Service providers must have efficient, well-organized production lines capable of rapid turnaround without compromising the quality of the iron castings.

Adapting to Changing Demands with Agile Manufacturing

Flexibility and agility in manufacturing are crucial for adapting to the ever-changing demands of the aerospace industry. Providers must be able to adjust their production schedules and processes quickly in response to their clients’ evolving needs.

Quality Control Measures

Quality control is the cornerstone of aerospace manufacturing. Iron casting service providers must have stringent quality control measures in place to ensure that every component meets the industry’s high standards.

Comprehensive Testing for Uncompromised Quality

From dimensional inspections to material testing, comprehensive quality control processes are vital to ensure that each casting is free from defects and meets all required specifications. Providers must employ a variety of testing methods, including non-destructive testing techniques, to validate the integrity of their castings.

Continuous Improvement for Optimal Performance

A commitment to continuous improvement in quality control measures is vital. Providers should regularly review and refine their quality control processes to keep pace with the technological advancements and evolving standards of the aerospace industry.

Supply Chain Reliability and Logistics Support

The robustness of a supply chain can often be the defining factor in the fast-paced aerospace industry, where every second counts and delays can lead to significant financial losses or safety risks.

Ensuring a Dependable Supply Chain

A dependable supply chain is essential for iron casting service providers, particularly in the aerospace sector. Providers must demonstrate a track record of reliable material sourcing, inventory management, and an ability to handle unexpected disruptions without impacting the client’s operations.

Streamlined Logistics for On-Time Delivery

Streamlined logistics are not just about delivering on time; they’re about precision timing and the flexibility to adapt to clients’ evolving needs. An iron casting service provider must have established logistics protocols that ensure each part arrives at its destination in the shortest time possible and in perfect condition.

Cost-Effectiveness and Value Engineering

In an industry where the costs of design and production can escalate quickly, providing cost-effective solutions without compromising quality is a delicate balance that iron casting service providers must achieve.

Balancing Quality with Affordability

Balancing the highest quality standards with affordability is a challenge. Service providers need to employ value engineering practices to reduce costs where possible while maintaining the integrity and performance of the aerospace components they produce.

Innovative Approaches to Reduce Production Costs

Innovative approaches to production, such as employing waste-reducing manufacturing techniques or optimizing design for more efficient material usage, can significantly reduce costs. Providers must continuously seek out and implement these innovations to offer competitive pricing to their clients.

After-Sale Service and Support

After-sale service and support are what often distinguishes an average service provider from a great one. In the aerospace industry, this support is critical due to the long lifecycles and high stakes involved in each component.

Offering Comprehensive After-Sale Services

Comprehensive after-sale services, including troubleshooting, technical support, and part replacement, are vital. A service provider must have a dedicated support system in place to address any issues that may arise after the delivery of the castings.

Building Long-Term Relationships Through Support

Building long-term relationships with clients through robust after-sale support can lead to repeat business and recommendations—a key to success in the aerospace industry.

Sustainability and Environmental Compliance

Sustainability is no longer an option but a requirement in modern manufacturing, especially in industries like aerospace, which are under increasing scrutiny for their environmental impact.

Implementing Eco-Friendly Practices

Implementing eco-friendly practices in iron casting processes is crucial. This includes everything from using recycled materials to employing energy-efficient machinery and reducing emissions throughout the production process.

Meeting Environmental Regulations

Meeting stringent environmental regulations is not just about compliance; it’s about taking responsibility for the planet. Service providers must show that they are not only meeting current regulations but are also prepared for future environmental challenges.

Case Studies: Successful Aerospace OEM Iron Castings

Case studies of successful projects can provide valuable insights into a service provider’s capabilities. They offer tangible evidence of their ability to meet the complex demands of aerospace OEM part production.

Learning from Past Successes

Each case study is a learning opportunity. They allow potential clients to see how the provider has navigated challenges in the past and how they might approach future projects.

Demonstrating Proven Competence

Through case studies, service providers can demonstrate their proven competence in delivering quality iron castings for aerospace applications, showcasing their problem-solving skills and ability to innovate.

Tips for Communicating with Iron Casting Service Providers

Effective communication is the cornerstone of any successful partnership, especially when dealing with the complexities of aerospace OEM parts production. Clear, concise, and frequent communication can ensure that projects stay on track and meet all necessary criteria.

Establishing Clear Communication Channels

It’s imperative to establish clear communication channels from the outset. This means determining the main points of contact, preferred communication methods, and regular update schedules to ensure everyone is on the same page throughout the production process.

Detailing Specifications and Expectations

Providing detailed specifications and clear expectations is essential to avoid misunderstandings. This includes technical requirements, timelines, and quality standards, all of which should be documented and agreed upon before production begins.

Conclusion: Integrating Key Considerations in Decision-Making

Selecting an iron casting service provider for aerospace OEM parts is a multifaceted decision that requires careful consideration of each provider’s capabilities and how they align with the specific needs of the project.

Weighing All Factors for Informed Decision-Making

An informed decision takes into account all the factors discussed—from the quality of materials and precision of castings to certifications, experience, technological capabilities, and beyond. It’s about weighing the strengths and potential weaknesses of each provider to determine the best fit.

The Partnership Approach to Iron Casting Services

Ultimately, selecting a service provider should be about forming a partnership. It’s a collaborative relationship that thrives on mutual trust, shared goals, and a commitment to excellence in producing aerospace OEM parts that meet the highest standards of quality and reliability.

Emphasizing the Value of Long-Term Collaborations

The aerospace industry’s demands do not end with the delivery of parts. Long-term collaboration with an iron casting service provider ensures that OEM parts are continually improved and that any arising issues can be promptly addressed.

The Importance of Post-Delivery Evaluation

Post-delivery evaluation is crucial for continuous improvement. Providers should work with clients to assess the performance of their castings and use this feedback to enhance their processes and output.

Commitment to Evolution and Growth

The best service providers are those committed to evolution and growth. They view each project as an opportunity to learn and improve, ensuring that they remain at the forefront of the industry and continue to provide their clients with the best possible service and products.

Navigating Future Challenges Together

The aerospace industry is constantly advancing, and the challenges of today may not be the same as those of tomorrow. A strong partnership with an iron casting service provider means facing future challenges together, with a shared commitment to innovation and excellence.

Preparing for Technological Advancements

Staying prepared for the next wave of technological advancements is essential. Providers need to be proactive in adopting new technologies and methodologies that can enhance the production of aerospace OEM parts.

Collaborative Problem-Solving for Unforeseen Issues

When unforeseen issues arise, having a service provider that excels in collaborative problem-solving can make all the difference. Such a provider won’t just offer solutions but will work closely with clients to implement them effectively.

Final Thoughts: Selecting the Right Partner for Iron Casting Services

In conclusion, selecting the right iron casting service provider for aerospace OEM parts is about much more than just the initial capabilities. It’s about finding a partner who will work with you through every challenge and who will be as committed to your products’ success as you are.

The Journey Beyond the Contract

The journey with a service provider goes well beyond the signing of a contract. It is an ongoing partnership that can have a significant impact on the quality, safety, and reliability of aerospace OEM parts.

Making the Choice with Confidence

By considering the detailed factors outlined in this article, you can make your choice of an iron casting service provider with confidence, knowing that you have thoroughly evaluated their ability to meet your specific needs and the rigorous demands of the aerospace industry.

Forging Ahead: The Continuous Journey in Aerospace Iron Casting Partnerships

The relationship with an iron casting service provider is not a static one; it’s a dynamic journey that evolves as both parties strive for excellence in the fast-paced and ever-advancing aerospace sector.

The Role of Feedback Loops in Quality Enhancement

Effective feedback mechanisms are crucial for the ongoing improvement of iron casting processes. Regular reviews and open communication channels can help in fine-tuning production methods, leading to consistently better outcomes with each batch of aerospace components delivered.

Adapting to Industry Shifts with Agility

The ability to adapt to industry shifts is a hallmark of a top-notch iron casting service provider. A partner who monitors aerospace trends and responds with agility, adjusting their processes and offerings, can provide a significant competitive edge.

The Strategic Advantage of Advanced R&D Capabilities

Innovation in iron casting, particularly for aerospace applications, is often driven by robust research and development (R&D) capabilities. Selecting a service provider who invests in R&D can lead to groundbreaking advancements in OEM part production.

Investing in the Future of Aerospace Castings

A service provider who dedicates resources to R&D is not just improving current processes; they are paving the way for future innovations that can redefine what’s possible in aerospace component manufacturing.

R&D: The Pathway to Next-Generation Aerospace Solutions

Through active R&D efforts, service providers can develop next-generation casting solutions, such as lighter, stronger materials or more efficient production techniques, that push the boundaries of aerospace engineering.

Envisioning the Future with Sustainability in Mind

As the aerospace industry looks to the future, sustainability becomes an increasingly critical factor in the selection of all partners and suppliers, including iron casting service providers.

The Imperative of Eco-Friendly Manufacturing Practices

Service providers that employ eco-friendly manufacturing practices demonstrate a commitment to the future—a trait that is highly valued in an industry looking to minimize its environmental footprint.

Sustainable Practices as a Competitive Differentiator

A provider’s commitment to sustainability can serve as a competitive differentiator, aligning with the values of aerospace companies that prioritize environmental stewardship.

Partnering for Success: The Ultimate Goal in Aerospace Iron Casting

The ultimate goal of any partnership is success—a concept that encompasses not only the quality of the parts produced but also the overall health of the relationship between the aerospace company and the iron casting service provider.

Success Through Synergy and Shared Vision

Success comes through the synergy of a shared vision for quality, performance, and innovation. When both parties work towards common goals, the results can be outstanding.

Long-Term Commitments Yielding Fruitful Outcomes

Long-term commitments between aerospace companies and iron casting providers can yield fruitful outcomes, with shared experiences and knowledge leading to a deepening of expertise and capabilities.

Integrating Advanced Analytics for Strategic Decision-Making

In the modern era, data is king. Integrating advanced analytics into the iron casting process can provide strategic insights that drive better decision-making and lead to superior aerospace OEM parts.

Leveraging Data for Continuous Improvement

A service provider that leverages data effectively can continuously refine their casting processes, leading to improved quality, efficiency, and performance of aerospace components. The use of data analytics helps in identifying patterns and potential areas of improvement that might not be visible to the naked eye.

Predictive Analytics for Proactive Quality Management

Predictive analytics can play a significant role in proactive quality management. By analyzing data trends, service providers can anticipate potential issues and implement corrective measures before they affect the production line, ensuring that the quality remains consistent and reliable.

Embracing the Digital Transformation in Iron Casting

Digital transformation is reshaping the manufacturing landscape, and the iron casting industry is no exception. Embracing digital technologies is essential for maintaining a competitive edge in the aerospace sector.

The Impact of Digitalization on Production Efficiency

Digitalization can significantly enhance production efficiency. From digital twin technology that creates virtual replicas of physical castings to IoT-enabled machinery that provides real-time monitoring, the opportunities for efficiency gains are substantial.

Digital Workflows and the Future of Aerospace Manufacturing

Implementing digital workflows can streamline every aspect of the iron casting process, from initial design to final quality control. This not only speeds up production but also increases accuracy and reduces the likelihood of errors.

Crafting a Resilient and Responsive Supply Chain

In an industry where delays can be costly, crafting a resilient and responsive supply chain is critical. The right iron casting service provider will have strategies in place to ensure that the supply chain can withstand various challenges without disruption.

Building Redundancy into the Supply Chain

Building redundancy into the supply chain can protect against unforeseen events, from natural disasters to material shortages. This involves creating backup plans and alternative sources for critical materials and components.

Responsive Supply Chain Management for Timely Deliveries

A responsive supply chain management system ensures that iron castings are delivered on time, every time. This requires a well-coordinated effort across various departments and, often, across different companies and geographies.

Elevating the Iron Casting Experience for Aerospace Excellence

The iron casting experience must be elevated to meet the exacting standards of aerospace excellence. This involves not just the technical aspects of production but also the service and support that surround it.

Personalized Customer Experiences in a Technical Field

Even in a technical field like iron casting, providing a personalized customer experience can set a service provider apart. This includes understanding client needs, offering tailored advice, and being available to address concerns and answer questions throughout the production process.

Service Excellence as a Hallmark of Quality

Service excellence should be a hallmark of quality for iron casting service providers in the aerospace industry. This commitment to service enhances the overall customer experience, building trust and fostering long-term relationships.

Nurturing Innovation in Iron Casting for Aerospace Applications

Innovation is the lifeblood of aerospace manufacturing, necessitating iron casting service providers to be not just suppliers but innovators in their own right.

Fostering a Culture of Innovation

Service providers must foster a culture of innovation within their operations, encouraging the exploration of new ideas and the adoption of breakthrough techniques that can lead to the next generation of aerospace iron castings.

Collaborative Innovation for Tailored Solutions

Collaboration between aerospace companies and iron casting providers can lead to tailored solutions that address specific challenges. This collaborative approach to innovation ensures that the final product is not just a component but a solution optimized for its intended application.

Commitment to Excellence in Every Casting

A commitment to excellence is what distinguishes the best in the business. For iron casting service providers in the aerospace industry, this commitment must be unwavering and evident in every product they deliver.

The Pursuit of Perfection in Iron Castings

The pursuit of perfection might seem like a lofty goal, but in aerospace, it is the standard. Service providers must strive for this level of quality in every casting, knowing that each piece is critical to the safety and performance of the aircraft.

Quality as the Cornerstone of Aerospace Iron Casting

Quality is the cornerstone upon which the reputation of a service provider is built. It is a comprehensive concept that encompasses every aspect of the casting process, from design and material selection to production and finishing.

The Strategic Significance of Customized Iron Casting Capabilities

Customized iron casting capabilities are strategically significant for aerospace OEMs. The ability to produce bespoke components that fit specific design parameters is not just a service but a strategic capability that can be a differentiator in the market.

Aligning Custom Capabilities with Aerospace Needs

Service providers must align their custom capabilities with the evolving needs of the aerospace industry, ensuring that they can respond swiftly and effectively to the unique demands of each project.

The Role of Custom Castings in Aerospace Innovation

Custom castings play a significant role in aerospace innovation. They allow for the exploration of new designs and the integration of advanced features that can improve the performance and efficiency of aerospace systems.

A Synergistic Approach to Iron Casting for Aerospace

In concluding, selecting the right iron casting service provider for aerospace OEM parts is a critical decision that requires a strategic and synergistic approach.

The Sum Greater Than the Parts

The relationship between an aerospace company and an iron casting provider is symbiotic, with the sum of the partnership being greater than the individual contributions. It’s about creating a whole that is more robust, innovative, and successful than the separate parts could ever be.

The Path Forward in Aerospace Manufacturing

The path forward for aerospace manufacturing is clear: it requires a partnership that is built on trust, driven by innovation, and dedicated to achieving excellence in every aspect of the production process. It’s a path that will be shaped by the providers who understand the importance of their role and are committed to pushing the boundaries of what’s possible in iron casting for aerospace applications.