Cast Iron Shrinkage Defects

/0 Comments/in Company News/by Yide CastingCast iron shrinkage defect has a great influence on the quality of cast iron. It will reduce the tensile strength and elongation, thus causing the iron casting to crack or penetrate in the shrinking area.

Today, based on my work experience at Yide Casting, I will introduce you to three types of shrinkage.

1. Sink on the surface

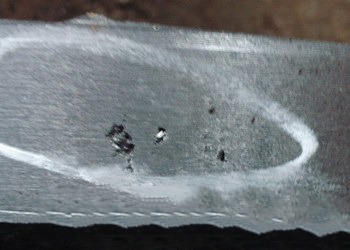

On the rough casting surface, you can see sinking pits. These pits are caused by shrinkage below the surface. Just like the photo below. This shrinkage will affect the size of the area and affect its physical properties. Generally, this shrinkage is unacceptable.

2. Large shrinkage holes inside of cast iron

You will not see this shrinkage on the surface. But after processing, this will be very obvious. You will see many large and small pores in the constricted area. Of course, this shrinkage is also unacceptable and very harmful to the application.

3. Small shrinkage holes inside of cast iron

Sometimes, after processing, you will see very small pores. Sometimes they cannot even be seen with the naked eye, but they can be inspected with a magnifying glass. Or, sometimes, you can refine them through water pressure or oil pressure testing. These shrinkages will cause the low density of cast irons, making them unable to withstand high pressures.

Obviously, shrinkage is very harmful to iron castings. The main reason for the shrinkage is the unreasonable casting process, especially the gate size. After the shrinkage is found, the iron casting plant should adjust its gate system.

However, since most shrinkage defects are under the cast iron surface, how should we check?

1. Generally, you can allow the supplier to perform roughing, so that they can find shrinkage after processing. This method is the most obvious and economical method, because most iron foundries in China have in-house rough machining capabilities.

2. For the pump body or valve body, you can conduct a water pressure test or ask your supplier to conduct a random test on them. Although this method cannot guarantee that all castings are qualified, at least some problems will be found.

3. You can cut off the sensitive position to check the shrinkage rate. According to our experience, shrinkage usually occurs in the gate area and certain corner areas. Therefore, after finding the shrinking position, you can focus on checking these positions in the batch inspection. You can just cut off these locations with a saw, or you can ask the supplier to cut off these locations that may cause shrinkage according to your instructions.

Manuel Hidrolik Palet Krikosu Bakımı ve Genel Arızaları

/0 Comments/in Company News/by Yide CastingManuel Hidrolik Palet Krikosu Bakımı ve Genel Arızaları

Bugün sizlere manuel hidrolik transpalet bakım ve genel arızalarını aşağıdaki gibi tanıtacağız.

Günlük bakım:

1. Yağ ekleme

Yağ seviyesini ayda bir kontrol edin. 32# hidrolik yağ kullanmanızı öneririz.

2. Egzoz

Pompa gövdesinin taşınması veya ters çevrilmesi nedeniyle, hidrolik pompaya hava girmesi muhtemeldir. Bu, yükselen konumda basınç bastırıldığında yükün kaldırılamamasına neden olacaktır. Egzozu aşağıdaki adımlara göre çalıştırabilirsiniz: tutamağın üst kısmını aşağı konuma çekin, ardından yukarı kaldırın. Bu nedenle birkaç kez tekrarlayın.

3. Günlük muayene ve bakım

Rutin bakım vazgeçilmezdir ve odak noktası tekerleklerin, göbek ekseninin ve paçavraların bakımı olmalıdır. Elleçleme bittiğinde çatalın üzerindeki eşyaları çıkarmalı ve çatal çerçevesini en alt konuma indirmeliyiz.

4. Yağlayıcı

Tüm yatakları ve milleri yağlama yağı ile eklemeliyiz. Tüm hareketli parçalara yalnızca aylık aralıklarla veya her kapsamlı inceleme sırasında yağlama yağı eklememiz gerekiyor.

Yaygın hatalar:

Hata 1: Çatal en yüksek konuma yükselemiyor

Neden analizi: yetersiz hidrolik yağ

Onarım yöntemi: hidrolik yağ ekleyin

Hata 2: Çatal yükselmiyor

Neden analizi: Hidrolik yağda kirlilik var, basınç tahliye valfi düzgün ayarlanmamış veya hidrolik yağında hava var.

Onarım yöntemi: temiz hidrolik yağı değiştirin, ayar vidasını ayarlayın, havayı alın.

Hata 3: Çatal düşmüyor

Neden analizi: dengesiz yük nedeniyle silindirin piston kolu deforme olmuş, dengesiz yük nedeniyle parçalar hasar görmüş veya deforme olmuş ve basınç tahliye valfi düzgün ayarlanmamış

Bakım yöntemi: piston çubuğunu veya silindiri değiştirin, ilgili parçaları onarın veya değiştirin, ayar vidasını ayarlayın,

Hata 4: Sızıntı

Neden analizi: aşınmış veya hasarlı contalar, çatlamış veya aşınmış parçalar

Onarım yöntemi: yeni contaları değiştirin, yeni parçaları kontrol edin ve değiştirin

Hata 5: Basınç serbest bırakılmadığında çatal düşüyor

Sebep analizi: hidrolik yağında kirlilik, hidrolik yağında hava olabilir, conta aşınmış veya hasarlı olabilir veya basınç tahliye valfi düzgün ayarlanmamış olabilir.

Bakım yöntemi: temiz hidrolik yağı değiştirin, havayı alın, yeni contaları değiştirin, ayar vidalarını ayarlayın

Advantages and Disadvantages of Stainless Steel Casting Process

/0 Comments/in Company News/by Yide CastingAdvantages and disadvantages of stainless steel casting process

Everyone in the casting industry knows a fact. That is the mechanical properties of stainless steel casting are higher than that of cast iron, but its casting performance is worse than that of cast iron. Stainless steel casting belongs to investment or precision casting, with relatively high melting point. The molten steel is easily oxidized, due to poor fluidity and large shrinkage rate. From a practical perspective, stainless steel casting is suitable for casting of various types and alloys.

Advantages and disadvantages of the stainless steel casting process are as below:

First, due to the poor liquidity of the molten steel, the wall thickness of the steel castings should not be less than 8 mm, in order to prevent the cold shut and misrun. The structure of the pouring system strives to be simple, and the sectional dimension is larger than that of cast iron. Adopt dry casting or hot casting, and the casting temperature should be appropriately increased to 1520-1600 ℃. The fluidity can be improved since the casting temperature is high with large superheat, thus the liquid stays for a long time.

However, if the pouring temperature is too high, it will cause defects such as coarse grains, hot cracks, pores and sand burning. Therefore, the casting temperature of small, thin-walled and complex casting should be at the melting point +150 ℃; and of large, thick-walled casting +100 ℃.

We must take these measures to prevent the occurrence of shrinkage holes and cracks in stainless steel castings. 1. Making the wall thickness uniform, and avoid sharp and right angle structures, 2. Adding sawdust to sand mold, and coke to sand core. 3. Adopting hollow sand core and oil sand core to change the deformability and permeability of the sand mold and core.

The Density of Ductile Iron

/0 Comments/in Company News/by Yide CastingThe density of ductile cast iron is approximately 7.3 g/cm3, or 7.3 kg/liter, or 119.6 g/cm3. However, due to the material grade and shrinkage level, the density has a certain range of variation.

In other words, if the quality of pig iron used by the iron foundry is better and the shrinkage rate is smaller, then the density of ductile iron will be higher. Otherwise, the density of ductile iron will be lower. Therefore, it ranges from 7.1 to 7.3 g/cm3.

Iron foundries usually estimate the weight of rough castings by calculating the volume of ductile iron, so the density will be used. However, you cannot judge the quality of castings by density alone.

There are more factors that will affect it, such as spheroidization rate and cooling rate. Hence, it will be reasonable within this range.

2025 Made in China and ONE BELT, ONE ROAD Policy Impact on Iron Foundry

/0 Comments/in Company News/by Yide CastingWith the implementation of “Made in China 2025” and “One Belt One Road” construction, the rapid development of all walks of life will be promoted. At the same time, the scale of China’s metal casting enterprises is also increasing year by year.

With the rapid development of various application fields, industry concentration has gradually increased, and product quality has continued to improve. This shows that the foundry industry has entered a medium-to-high-speed development stage.

The China (Beijing) International Foundry Exhibition will continue to be held at the China International Exhibition Center (new hall). In this way, it promotes the innovation and development of the foundry industry and promotes in-depth cooperation and exchanges between enterprises.

As a foundry with a history of more than 20 years, Yide Casting will take this opportunity to meet the needs of different customers in countries along the “Belt and Road” with high quality, high technology and high quality. Use better cast iron products to show the world the capabilities of China’s manufacturing.

About Yide Casting

Yide Casting is a professional casting & machining factory in China, specialized in green sand casting and clay sand casting. Otherwise, Yide casting has our patent JM heat exchanger for air conditioner…Read more.

Friendly link:

Contact information

- phone num:

+8613566559986 - WhatsAPP/ WeChat:

+8613566559986 Kevin - Email:

[email protected] - Address:No. 1328 Wenyi West Road, Cangqian Street, Yuhang District, Hangzhou Zhejiang

Service

Yide casting provides casting & machining service, which is a one-stop solution of casting parts.

Casting: green sand casting, shell sand casting

Machining.