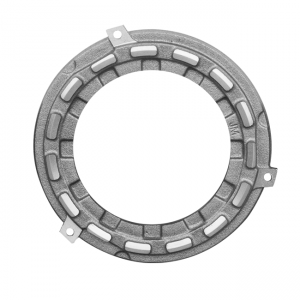

Cast Iron Motor Housing

| Cast Iron Motor Housing |

| Grey Cast Iron HT200 |

| BH 160-220 |

| Sand Casting, Green Sand Casting / Clay Sand Casting |

| 1.0-4.0kg / set |

| Spectrum Analyzer, Three-Coordinate Detector, Metallographic Analyzer, Tensile Testing Machine Imported From Germany. |

| Automobile Induatry |

YIDE

Cast Iron Motor Housing

Motor is a common equipment that converts electrical energy and kinetic energy into each other in our daily life. According to the size, motor is divided into large motors, medium motors and small motors; from watches to generator sets. The center of the common motor shaft in the market Height dimensions are generally 36#, 40 #, 45 #, 50 #, 56 #, 63 #, 71 #, 89 #, 90 #, 100 #, 112 #, 132 #, 150 #, 180 #, 200 #, 225 # 250 #, 280 #, 315 #, 355 #, 400 #, 450 #, 500 #, 560 #, 630 #, 710 #, 800 #, 900 #, 1000 #, etc.

Due to the different power and use environment of the motor, different sizes of motors should also use different housing materials. Generally, the housing of the motor above 63# is made of gray cast iron.

The advantages of gray cast iron motor housing are high hardness, high resistance to external pressure and deformation, and low cost as well. Gray cast iron motor housing can be installed in places with high driving force and the relatively poor environment. Therefore, gray cast iron is widely used in the field of motor housing accessories.

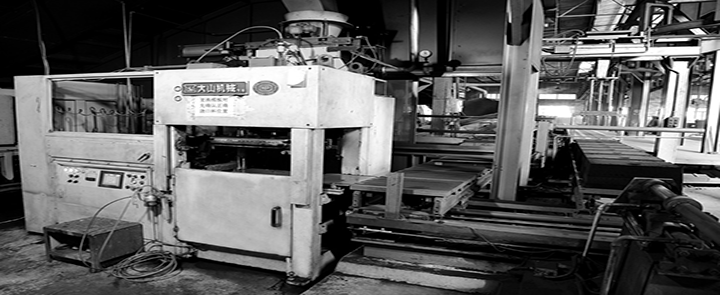

Yide casting is a leading casting supplier in China, specialized in casting & machining for 27 years, equipped with German imported casting equipment, own 2 automatic casting production lines, and manual lines.

Yide casting has enough ability to produce qualified best casting parts for you, sample first, production after deposit. If you are interested in car steel parts or casting iron parts, please don’t hesitate to contact us for more details.

Yide casting manufactures these grey iron casting products with a strict standard.

- Don’t allow any defects on the surface of truck casting items, such as porosity, trachoma and cold partition.

- The product burr should be handled cleanly, for better installing and using of our casting customer.

- It is absolute to manufacture a real dimensional accuracy of the machining not exceed the tolerance, according to your’ drawing requirements. Yide casting always designs a reasonable machining and processing steps to reduce the clamping step, so that Yide can ensure processing accuracy and maximize the production of casting products.

Electrophoresis Treatment of Iron Casting Parts

Yide iron casting always does electrophoresis treatments on the surface of the iron casting product, so that coated a protective film on the cast gray iron parts surface.

The electrophoresis treatments of casting items not only can prevent corrosion and rust during the use of the product effectively, but also decorate the iron cast items surface more beautiful and smooth.

| Product Name | Cast Iron Motor Housing |

| Casting Type | Grey Iron Casting |

| Casting Module | Sand Casting / Clay Sand Casting / Green Sand Casting |

| Casting Manufacturer | YiDe Iron Casting |

| Quality Control | Spectrum Analyzer, Three-Coordinate Detector, Metallographic Analyzer, Tensile Testing Machine Imported From Germany. |

| Standards | ASTM A48, ISO 185, DIN 1691, EN 1561, JIS G5501, UNI 5007, NF A32-101, BS 1452, IS 210, UNF, NBN 830-01, AS 1830, SS14 01, NS11 100 |

| Material Grade | HT200 |

| Application | Car Accessories |

| Machining Requirements | grinding to mirror for top and bottom side |

| Defects Requirements | Zero defects for both top and bottom side, and inside |

| Inspection Method | visual, dimensional, X-ray inspection |

| Exported to | USA |

Cast Iron Car Rocker Arm

-

Machine Molding

Yide iron casting factory comes from China, is a professional iron casting, steel casting and brass casting manufacturer, provides OEM service for our automatic trailer accessories casting customers.

The first step of an order beginning is to make a module according to your requirement. Yide has a high advance molding equipment to make automatic parts molding, can make a high hard sand molding according to the module design.

YiDe iron casting manufacturer has two types of sand to make casting module – reusable sand and disposable sand. Thus you can choose suitable sand according to your needs. Of course, the reusable sand module needs more cost than the disposable sand module.

-

Melting and Pouring

As you think, the raw material of iron casting is pig iron, Yide Stainless Casting needs to melt these pig iron, and pouring these liquid pig iron into the sand module so that we can get an original roughcasting part.

-

Inspection Before Producing

When the Yide iron casting factory gets an iron casting order, there will be some requirements of chemical composition, such as carbon.

So Yide stainless casting must have strict inspection before big production. -

Machining

After melting & pouring, passing the inspection, Yide will arrange the production of truck iron cast parts. Then do machining for these rough gray casting parts, make them look more beautiful, and have good dimensional accuracy according to the requirements.

Various CNC equipment and Machining Center can meet customers’ requirements for product processing technology and dimensional accuracy. The current accuracy of iron casting parts can reach 2U.

Final Quality Control of Casting Parts

JM iron casting manufacturer always has relative lodge cast iron types of equipment for quality inspection of JM raw iron material test and final casting parts.

Package of Cast Iron Car Rocker Arm

Yide casting package our casting grey iron products, ductile iron casting products or bronze/brass casting parts with fumigation-free wooden box, and the inside of the box is also separated by carton and partition board.

A customized package is available too.

The final packaging of Yide iron casting can be customized according to customer requirements to meet the different needs of different customers, such as wood carton for cast iron bathtub or cast iron radiators, hard carton for ductile cast iron pipe or some small truck parts.

Yide provides one-stop service for our casting iron customers.

Whatever from casting, processing, surface treatment, inspection or packaging, Yide casting strives to deliver the best shell casting & green sand casting products to our clients.

Quality and punctual delivery are the factory’s cooperation guidelines!

If you are interested in our customized iron casting products, and looking for OEM, ODM casting service, please feel free to contact us for more details and get a quick quote.