The Difference Between Ductile Iron Casting and Gray Iron Casting

The Difference Between Ductile Iron Casting and Gray Iron Casting

On the surface, ductile iron casting parts are similar to the grey iron casting items, we can not distinguish them from the surface, both of them have a roughcast surface. But we can distinguish them though cutting surface, filing test or percussion etc.

Here, we delve into these methods in detail, using eco-friendly terminology and long-tail keywords to enhance clarity and provide a comprehensive guide.

1. Cutting Surface Examination

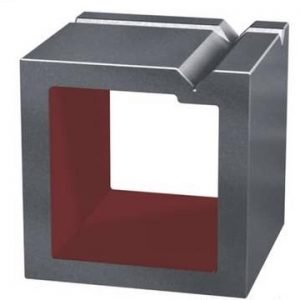

Check iron casting from the appearance

When a gray iron casting is cut, the exposed surface reveals a grayish, rough texture. This surface is characterized by visible graphite flakes, which give it a distinctive grainy appearance. These graphite flakes are usually flat and sharp-edged, contributing to the roughness of the surface. The texture is typically dull and lacks the metallic sheen found in other iron types.

In contrast, when a ductile iron casting is cut, the exposed surface exhibits a smoother, more metallic look. This surface is generally shiny and less grainy compared to gray iron. The absence of flaky graphite results in a cleaner, more uniform texture.

Check iron casting from the structure

The presence of flake graphite can often be observed with the naked eye or under low magnification. These flakes appear as irregular, thin lines dispersed throughout the iron matrix. This flaky structure is what imparts the name “gray iron,” as it reflects the gray coloration seen on the fracture surfaces.

Upon closer examination, especially under magnification, ductile iron reveals nodular or spheroidal graphite particles. These nodules are evenly distributed within the iron matrix, providing a more consistent and solid appearance. This spherical graphite structure is a key characteristic of ductile iron, contributing to its superior mechanical properties.

Filing Test

Way to check type of iron cast parts

To perform the filing test, use a standard metal file and file a small area of the gray iron casting. Ensure the file is applied with moderate pressure to observe the resulting texture and residue.

Gray iron will file easily, producing a powdery, dark gray residue. The filing action feels smoother due to the lubricating effect of the graphite flakes, which act as a natural lubricant during the cutting process. As you file, the surface may exhibit small grooves or scratches where the graphite flakes are removed, further highlighting the flaky nature of gray iron.

Similarly, file a small area of the ductile iron casting using the same metal file and moderate pressure.

Ductile iron is notably harder to file, generating less powder compared to gray iron. The filing action feels more resistant, indicating the material’s higher strength and toughness. The residue produced is finer and lighter in color, reflecting the different graphite structure. The surface will have a more polished appearance with fewer grooves, thanks to the nodular graphite that doesn’t flake off as easily as the graphite in gray iron.

Percussion Test (Sound Test)

Lightly strike the gray iron casting with a small hammer or metal rod. Ensure the strike is gentle enough to avoid damaging the part but firm enough to produce a sound.

Gray iron emits a dull, flat sound when struck. This sound lacks resonance and has a “dead” quality, largely due to the flake graphite structure. The graphite flakes dampen vibrations, preventing the material from producing a clear, ringing tone.

Similarly, strike the ductile iron casting with a hammer or metal rod using the same gentle but firm technique.

Ductile iron produces a clear, ringing sound upon being struck. This sound is more resonant and has a higher pitch compared to gray iron. The nodular graphite structure in ductile iron transmits vibrations more effectively, resulting in a bell-like tone that contrasts sharply with the dull sound of gray iron.

Summary of Tests

When you check the ductile iron casting and grey iron casting, you can use the cutting Surface Examination.

Gray iron casts will show a rough, dull, grainy surface with visible graphite flakes.

The ductile iron casting parts will be smoother, shiny surface with nodular graphite particles.

If you test the grey iron and ductile iron by filling test.

Gray iron is easier to file, producing a dark gray, powdery residue. The filing action feels smoother.

Ductile iron is harder to file, generating a finer and lighter residue. The filing action feels more resistant.

When you use percussion test.

Gray iron lmits a dull, flat, “dead” sound.

Ductile produces a clear, ringing, resonant sound.

Understanding the differences between gray iron casting and ductile iron casting is crucial for selecting the appropriate material for various engineering and industrial applications. These differences arise primarily from the microstructure and the resulting mechanical properties of each type of iron.

Aplication of gray iron and ductile iron

Gray iron is composed of graphite flakes within an iron matrix. These flakes disrupt the matrix, making it more brittle. With features of high compressive strength, excellent vibration damping, superior machinability, but lower tensile strength and ductility. Widely applied in engine blocks, machine tool frames, brake discs, manhole covers, and any application where vibration damping and compressive strength are essential.

Ductile iron contains spheroidal or nodular graphite particles within an iron matrix. This structure enhances the material’s strength and ductility. This casting parts features high tensile strength, excellent ductility and toughness, good fatigue resistance, and improved corrosion resistance. Widely used for automotive components like crankshafts and steering knuckles, pipes and fittings, agricultural and construction machinery parts, and any application requiring high strength and toughness.

How to select the type of iron casting for your right application

Selecting between gray iron and ductile iron depends on the specific requirements of the application, including mechanical properties, machinability, and cost considerations. By using simple tests such as cutting surface examination, filing test, and percussion test, you can reliably distinguish between gray iron casting parts and ductile iron casting parts. This distinction is crucial for ensuring the appropriate material is used for the intended application, ultimately leading to better performance and longevity of the parts.