Cast Iron Shrinkage Defects

Cast iron shrinkage defect has a great influence on the quality of cast iron. It will reduce the tensile strength and elongation, thus causing the iron casting to crack or penetrate in the shrinking area.

Today, based on my work experience at Yide Casting, I will introduce you to three types of shrinkage.

1. Sink on the surface

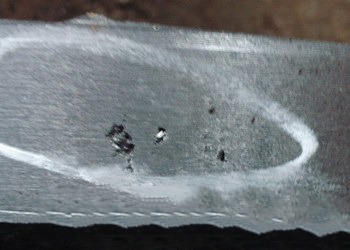

On the rough casting surface, you can see sinking pits. These pits are caused by shrinkage below the surface. Just like the photo below. This shrinkage will affect the size of the area and affect its physical properties. Generally, this shrinkage is unacceptable.

2. Large shrinkage holes inside of cast iron

You will not see this shrinkage on the surface. But after processing, this will be very obvious. You will see many large and small pores in the constricted area. Of course, this shrinkage is also unacceptable and very harmful to the application.

3. Small shrinkage holes inside of cast iron

Sometimes, after processing, you will see very small pores. Sometimes they cannot even be seen with the naked eye, but they can be inspected with a magnifying glass. Or, sometimes, you can refine them through water pressure or oil pressure testing. These shrinkages will cause the low density of cast irons, making them unable to withstand high pressures.

Obviously, shrinkage is very harmful to iron castings. The main reason for the shrinkage is the unreasonable casting process, especially the gate size. After the shrinkage is found, the iron casting plant should adjust its gate system.

However, since most shrinkage defects are under the cast iron surface, how should we check?

1. Generally, you can allow the supplier to perform roughing, so that they can find shrinkage after processing. This method is the most obvious and economical method, because most iron foundries in China have in-house rough machining capabilities.

2. For the pump body or valve body, you can conduct a water pressure test or ask your supplier to conduct a random test on them. Although this method cannot guarantee that all castings are qualified, at least some problems will be found.

3. You can cut off the sensitive position to check the shrinkage rate. According to our experience, shrinkage usually occurs in the gate area and certain corner areas. Therefore, after finding the shrinking position, you can focus on checking these positions in the batch inspection. You can just cut off these locations with a saw, or you can ask the supplier to cut off these locations that may cause shrinkage according to your instructions.

Leave a Reply

Want to join the discussion?Feel free to contribute!