Ductile Cast Iron EN-GJS-600-3

EN-GJS-600-3 ductile iron is a high grade material in European standard DIN EN 1563.

It is equal to GGG60 in DIN 1693, QT600-3 in China, A536 80-60-03 in USA ASTM, GS600-12 in Italy, FCD600 in Japan, FGS600-2 in France, FNG60-2 in Belgium, SJK-600 in Norway and ISO 1083 600-3.

Today, I will introduce the mechanical properties, chemical composition, foundries and castings of EN-GJS-600-3 for you.

Properties of EN-GJS-600-3 cast iron

Tensile strength ≥ 600 Mpa.

Yield strength ≥ 370 Mpa.

Elongation ≥ 3%.

No impact requirement.

Ductile cast iron EN-GJS-600-3 has high tensile strength, middle ductility and plasticity. It also has good wear resistance and shock absorption properties. That means its comprehensive material properties are very high.

It has good casting process performance. At the same time, it could be heat treated to improve the microstructure and mechanical properties.

Hardness of EN-GJS-600-3 cast iron

The hardness of this ductile cast iron grade is between 180-270 Brinell hardness.

Density of EN-GJS-600-3 cast iron

The density of this ductile iron grade is about 7.3 g/cubic centimeter, or 7.3 kg/liter.

Chemistry composition of EN-GJS-600-3 cast iron

According to the standard DIN EN 1563, the foundries could adjust the chemical composition as long as the mechanical and physical properties of the castings could meet the requirements in Standards.

The following chart is an approximate chemical composition range for your reference.

| DIN EN 1563 | ISO | C % | Si % | Mn % | P % | S % | |

| EN-GJS-600-3 | 600-3 | 2.5-3.6 | 1.8-2.8 | 0.3-0.7 | ≤0.08 | ≤0.02 |

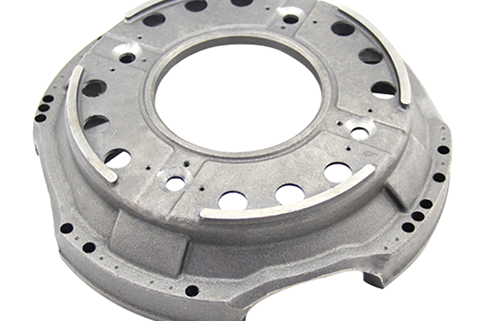

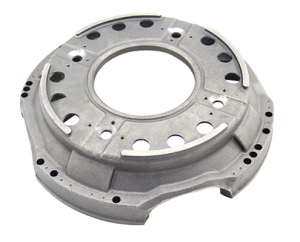

Foundry of EN-GJS-600-3 cast iron

Yide casting is an experienced casting foundry, specialized in casting iron for 28years, can manufacture the casting iron parts according to your drawing file and requirement. If you are looking for a casting manufacturer, please feel free to contact us for more details, and you are welcome to visit our factory for more details.

Leave a Reply

Want to join the discussion?Feel free to contribute!