Introduction of Iron Based Coated Sand Casting

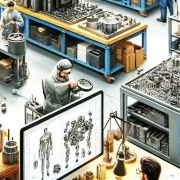

Brief introduction of iron based coated sand casting:

Iron based coated sand casting is a casting production technology. In the 1970s, Chinese foundry workers developed a special casting technology method, which is based on the research of domestic and foreign foundry counterparts, and in combination with China’s national conditions. It is different from sand casting, lost wax casting, V-shape casting, permanent mold casting, shell mold casting, paraffin casting, ceramic casting, steel shot casting and other casting methods. This method uses a metal model, and the cast iron cavity that is close to the shape of the casting as the sand box iron mold. And then the near-shaped iron mold is covered with a layer of 6~10mm of coated sand to form a mold for pouring into a casting.

-

The process of iron based coated sand casting includes:

Machine modeling-checking and closing the box-placing the sprue cup in the lock box-pouring-unpacking the casting-sand cleaning-modeling.

-

Features of iron based coated sand casting:

1. Having the characteristics of sand casting

That is, having a rigid sand mold shell, which makes the sand mold high in overall strength without deformation. At the same time, it has wide adaptability, easy demoulding of castings, reliable positioning and high precision.

2. Having the characteristics of coated sand shell casting.

The modeling is convenient and fast. No matter what the casting sand mold is, the molding can be completed within two or three minutes. The sand density and surface hardness of the mold are guaranteed by the equipment and are always consistent. And do not need to apply any paint. The smooth casting is obtained, and the shape and dimensional accuracy of the casting are improved.

3. Having the characteristics of metal mold casting.

The iron mold has obvious chilling effect during the crystallization process of molten metal. This can refine the grain size of the casting, thereby improving the overall strength of the casting. The presence of sand tires avoids the shortcomings of metal mold casting. Castings will not produce white holes. For iron castings, it can produce various materials in the as-cast state without heat treatment.

4. High precision

The mold composed of iron mold and thin sand tire has high rigidity, small deformation and fast cooling after locking. Meanwhile, the obtained casting has high dimensional accuracy, small machining allowance and compact structure. It is especially suitable for the production of ductile iron. At the same time, the method use the graphitization expansion of ductile iron to self-feed, and produce castings with less and no risers. Thus to obtain high-quality castings. Because the iron mold cools quickly, it is effective for the production of high-grade pearlite substrates. Rod and shaft castings are particularly advantageous.

5. High hardness

Under normal circumstances the hardness of castings produced by iron based coated sand casting is about 20 HB units higher than those produced by ordinary casting methods.

6. Low investment

Using the waste heat of the cast iron mold to solidify the coated sand produced by recycling, not only reduces electricity consumption, but also the casting process presents a closed cycle production state. In the meantime, the production area is small, requiring no sand treatment equipment, low investment and quick results.

7. Reuse of the mould

Due to the chilling of the iron mold, the molding sand will not be overfired. Not only can the molding sand be reused, but also because of the roasting during the pouring process, the molding sand (quartz sand) undergoes a phase change, and the thermal expansion coefficient of the sand is reduced from 15 to 5. Therefore, the old sand produced in the production process can also be recycled, which is in line with the development of circular economy.

8. Low rejection rate

Iron based coated sand casting is particularly suitable for the production of large batches of medium and small castings. If there are few replacements, the overall rejection rate can be reduced to about 3%.

9. Long service life

The service life of the iron mold with sand-coated iron mold can reach more than 10,000 times. However, under the influence of long-term repeated thermal expansion and contraction and the casting environment, additional maintenance is required.

Leave a Reply

Want to join the discussion?Feel free to contribute!