Spheroidizing Treatment Method of Ductile Cast Iron

Spheroidizing Treatment Method of Ductile Cast Iron

There are many spheroidizing methods for ductile iron castings. And the pour-over modification process is currently the most widely used spheroidizing method all over the world.

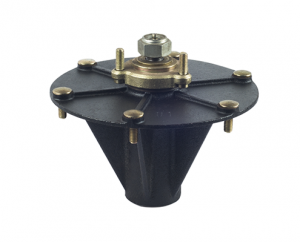

The treatment package used is usually a dam type spheroidizing treatment package. In order to reduce the intensity of the reaction between molten iron and magnesium, and the volatilization rate of magnesium vapor, the pour-over treatment process usually uses an alloy nodulizing agent with a lower magnesium content.

The process of spheroidizing treatment of ductile iron castings including the following steps.

First, put the nodulizing agent into one side of the dam, and cover the top with ferrosilicon alloy. And then cover it with rust-free iron filings, steel plate or other covering agent. When spheroidizing, the molten iron should be flushed into the other side of the molten iron ladle as much as possible.

The absorption rate of magnesium in the flushing method is generally 30% to 50%. There are three ways to improve the spheroidizing effect.

1. Increasing the ratio of the height to the diameter of the treatment package.

2. Adopting low-magnesium alloy spheroidizing agent.

3. Reasonable molten iron temperature and covering dosage.

The advantages of the pour-over method are simple processing and equipment, easy operation, greater flexibility in production, and low technical content required. However, the disadvantage is that the spheroidization process is higher pollution by magnesium light and smoke, and the absorption rate of magnesium is low.

There is also a subcontracting method, which uses pure magnesium as a nodulizing agent.

The subcontracting method is suitable for processing molten iron with high sulfur content. At the same time, this method can better separate impurities such as magnesium sulfide and silicate from the molten iron. The reaction with molten iron is not very violent and the temperature of molten iron is less. Therefore, it is safe to use, and the absorption rate of magnesium can reach 60% to 80%.

The specific process flow contains the following steps.

1. Before the spheroidizing treatment, place the subcontractor horizontally.

2. Inject quantitative molten iron, and then add the nodulizing agent to the reaction chamber.

3. Lock the closing device, and then close the ladle cover.

4. Turn the molten iron ladle to stand upright.

By now, the molten iron enters the reaction chamber through the small holes in the reaction chamber. The flow rate is related to the area of the small holes and the static pressure in the molten iron ladle.

Magnesium vaporizes by heating, forming a magnesium vapor pressure in the reaction chamber. When the pressure exceeds the static pressure of the molten iron in the ladle, the molten iron stops entering, and the latent heat of vaporization of magnesium reduces the temperature in the reaction chamber. And the vapor pressure also drops, and the molten iron enters the reaction again. This kind of automatic adjustment can make magnesium react with molten iron more smoothly.

The spheroidizing process of the subcontracting method also produces large magnesium light and smoke, and the small holes in the reaction chamber in the subcontracting are easily blocked by molten iron or molten slag. It is troublesome to clean and maintain the size of the small holes. The spheroidizing method is difficult to continuously process the molten iron.

Yide Casting is a professional iron foundry in China, with 28 years’ casting and machining experience, provides ductile iron cast, gray iron cast, brass iron cast services for our customers, you only need to show us your drawing file and requirements, we will ensure the final solution and send you a cast sample to check the quality and parameters, if you are looking for professional casting foundry, please don’t hesitate to contact us for more details.

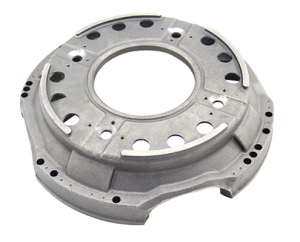

Due to the different materials, the distinction between cast aluminum and cast iron is quite obvious. Today, Yide Casting will share the differences with you, so that you can choose the right material for your castings.

Due to the different materials, the distinction between cast aluminum and cast iron is quite obvious. Today, Yide Casting will share the differences with you, so that you can choose the right material for your castings.