How a Forklift Oil Pump Works in the Hydraulic System?

-

Working principle of forklift hydraulic system

The basics of the hydraulic system go like this: Confined oil has pressure on it from one side. That pressure forces the oil against a piston on the other side of the container. That transfers energy into the piston, forcing it upward. The piston cannot move in the opposite direction unless the pressure is released. In terms of the forklift hydraulic system, the pistons raise the forks and keep them lifted until the hydraulic pressure is released by the operator.

-

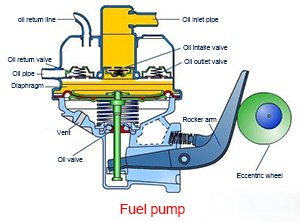

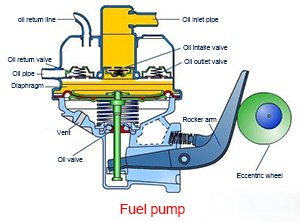

Composition and function of forklift oil pump

Forklift piston oil pump is mainly composed of small forklift parts such as pump body, seal, oil outlet and inlet valve etc. Its function is to suck the oil used by the forklift from the oil tank to generate a certain pressure of the oil to overcome the resistance of the oil filter and pipeline, and to ensure continuous delivery of sufficient oil to the oil injection pump.

-

The forklift oil pump is installed in the forklift hydraulic system. Now, let me introduce the safety technical requirements of forklift hydraulic system accessories.

Forklift hydraulic system accessories occupies an important position in the use of forklifts. Forklift working device accessories mainly rely on hydraulic system for lifting, tilting and other actions. The working condition of the forklift hydraulic system will directly affect the working condition of the forklift. Once the hydraulic transmission system parts of the forklift have malfunctions, it will inevitably bring direct unsafe consequences. Therefore, it is important for the safe operation and driving of the forklift to maintain the hydraulic system in strict accordance with the safety technical requirements. The following are the safety technical requirements for forklift hydraulic system:

-

The oil level of the oil tank shall not be lower than the oil mark line of the oil level indicator. And the application of hydraulic oil shall comply with the regulations. At the same time, the oil shall be clean, and the filters shall not be blocked.

-

The overflow valve should be sensitive and reliable; The nuts of the adjusting bolts must be complete; And the pressure regulation should meet the equipment requirements.

-

The components, pipelines and joints of the forklift hydraulic system should be unblocked. There is no leakage of the seal, no friction with other accessories, and no aging or deterioration of the rubber hose. The internal leakage should be within the allowable range.

-

The compression spring of the forklift multi-way valve must be intact, and the valve stem can be quickly back to position when eliminating the external force. The joystick should have a certain strength and rigidity, the surface should be smooth, without deformation. And the joystick should be positioned reliably, and not displaced due to vibration. The overflow valve should be sensitive and fully open when overloaded by 25%. And the nuts of the adjusting bolts should be fully tightened.

-

Crawling, stagnation and significant impact should not occur within the rated speed range of each hydraulic cylinder.

-

Each high-pressure hose should undergo a pressure test and meet the specified requirements.

-

Various control valves should be safe, reliable, and sensitive.

Leave a Reply

Want to join the discussion?Feel free to contribute!