AISI 1020 Carbon Steel

AISI 1020 Carbon Steel

AISI 1020 Carbon Steel is a high grade steel material. Today, we will introduce the chemical composition, physical and mechanical properties and equivalent material grades of this grade material for you.

Chemical Composition

| Element | Content (%) |

| Manganese, Mn | 0.30-0.60 |

| Carbon, C | 0.18-0.23 |

| Sulfur, S | 0.05 (max) |

| Phosphorous, P | 0.04 (max) |

| Iron, Fe | Balance |

Physical Properties

| Properties | Metric | Imperial |

| Density | 7.87 g/cm3 | 0.284 lb/in3 |

Mechanical Properties

| Properties | Metric | Imperial |

| Tensile strength | 420 MPa | 60900 psi |

| Yield strength | 350 MPa | 50800 psi |

| Modulus of elasticity | 205 GPa | 29700 ksi |

| Shear modulus (typical for steel) | 80 GPa | 11600 ksi |

| Poisson’s ratio | 0.29 | 0.29 |

| Elongation at break (in 50 mm) | 15% | 15% |

| Hardness, Brinell | 121 | 121 |

| Hardness, Knoop (converted from Brinell hardness) | 140 | 140 |

| Hardness, Rockwell B (converted from Brinell hardness) | 68 | 68 |

| Hardness, Vickers (converted from Brinell hardness) | 126 | 126 |

| Machinability (based on AISI 1212 steel. as 100 machinability) | 65 | 65 |

Fabrication and Heat Treatment

- Compared with AISI 1112 carbon steel, AISI 1020 carbon steel has good workability, reaching 65%.

- Thanks to the high ductility, it is easy to form AISI 1020 carbon steel using all conventional methods.

- It is easy to weld this alloy by using all traditional methods.

- This Alloy can be hardened by heating at 815-871°C (1500-1600°F), then water quenching and temperature adjustment.

- AISI 1020 carbon steel should be forged at a temperature of 1260°C (2300°F) to 982°C (1800°F).

- AISI 1020 carbon steel can be hot processed in the temperature range of 482 to 649°C (900 to 1200°F).

- All conventional methods can be used to cold work AISI 1020 carbon steel. If cold working is performed for a long time, stress relief annealing is recommended.

- The alloy can be fully annealed between 871-982°C (1600 to 1800°F), and then slowly cooled in the furnace. This will provide the alloy with a tensile strength of approximately 65 ksi. If required, stress relief annealing can be performed at 538°C (1000°F).

- After tempering, it should be heat treated and quenched at a temperature of 315 to 538°C (600 to 1000°F) according to the required strength level. For example, tempering at 538°C (1000°F) can provide the alloy with a tensile strength of 90 ksi.

- AISI 1020 carbon steel can be hardened by cold working and heat treatment, quenching and tempering.

Applications

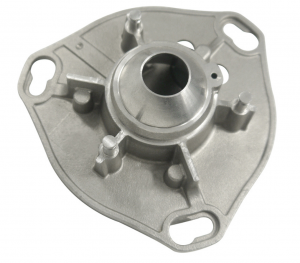

AISI 1020 carbon steel is used for simple structural applications, such as cold bolts. Usually used when the surface is hardened.

At the same time, it is also suitable for producing pins, shafts, chains, lightly stressed gears, hard wearing surfaces, and case hardened components where core strength is not essential.

Yide casting is an experienced iron casting foundry, provides iron casting service and machining service, we also have a cast steel casting factory to cooperate, if you have any casting requirements, please don’t hesitate to contact us for more details.

Leave a Reply

Want to join the discussion?Feel free to contribute!