Machining Surface Finish Chart (2)

Machining surface finish

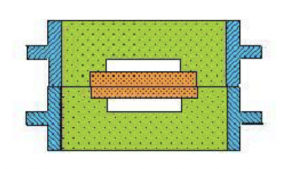

Surface finish is another term for surface roughness. The surface finish is put forward according to the human visual point of view. Meanwhile, the surface roughness is put forward according to the actual surface micro-geometry. Because of its conformity with international standards (ISO), China adopted surface roughness after the 1980s and abolished surface finish. After the promulgation of the national standards for surface roughness GB3505-83 and GB1031-83, the surface finish is no longer used.

There are corresponding comparison tables for surface finish and surface roughness. Roughness has a calculation formula for measurement, while smoothness can only be compared with a model gauge. Therefore, the roughness is more scientific and rigorous than the finish.

Machining surface finish and surface roughness comparison table

|

surface finish value |

surface roughness value Ra (μm) |

1) Surface condition |

2) Processing method |

3) Application examples |

|

▽1 |

400~800 |

|||

|

▽2 |

200~400 |

1) Obviously visible tool marks |

2) Rough turning, boring, planing, drilling |

3) Surface after rough machining, 2 Welding seam before welding, rough drilling wall, etc. |

|

▽ 3 |

100~200 |

1) Visible tool marks |

2) Rough turning, planing, milling, drilling |

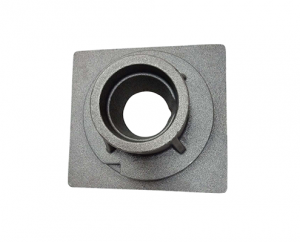

3) General non-bonding surfaces, such as shaft end faces, chamfers, side surfaces of gears and pulleys, non-working surfaces of keyways, and weight-reducing hole surfaces |

|

▽4 |

50~100 |

1) Visible machining traces |

2) Turning, boring, planing, drilling, milling, filing, grinding, rough reaming, milling teeth |

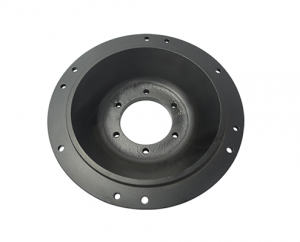

3) Matching surfaces of unimportant parts, such as pillars, brackets, shells, bushes, shafts, covers, etc. End face. The free surface of the fastener, the surface of the through hole of the fastener, the non-centering surface of the inner and outer splines, the round surface of the gear top ring that is not used as a measurement reference, etc. |

|

▽5 |

25~50 |

1) Processing traces are slightly visible |

2) Turning, boring, planing, milling, scraping 1~2 points/cm^2, drawing, grinding, filing, rolling, milling |

3) Connecting with other parts does not form a matching surface, such as The end face of the box, shell, end cover and other parts. Fixed bearing surfaces that require centering and matching characteristics, such as centering shafts, working surfaces of keys and keyways. The surface of the fastening thread is not important. Surfaces that need knurling or oxidation treatment |

|

▽6 |

12.5~25 |

1) Can’t see the processing traces |

2) Turning, boring, planing, milling, reaming, drawing, grinding, rolling, scraping 1~2 points/cm^2 milling teeth |

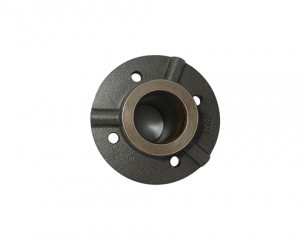

3) Mounting the housing hole of G-class bearing with a diameter of more than 80mm , Ordinary precision gear tooth surface, positioning pin hole, surface of V-belt pulley, outer diameter of inner spline centered by outer diameter, centering shoulder surface of bearing cap |

|

▽7 |

6.3~12.5 |

1) The direction of the machining traces can be distinguished |

2) Turning, boring, drawing, grinding, milling, scraping 3-10 points/cm^2, rolling |

3) Surfaces that require centering and matching characteristics, such as taper pins and cylinders The surface of the pin, the shaft diameter and housing hole matched with the G-class precision rolling bearing, the shaft diameter for medium-speed rotation, the shaft diameter and the housing hole of the E and D rolling bearing with a diameter of more than 80mm, and the centering of the inner and outer splines Inner diameter, outer spline key side and centering outer diameter, interference fit IT7 hole (H7), clearance fit IT8~IT9 hole (H8, H9), ground gear surface, etc. |

|

▽8 |

3.2~6.3 |

1) Micro-identification of the direction of the machining traces |

2) Reaming, grinding, boring, pulling, scraping 3-10 points/cm^2, rolling |

3) The mating surface that requires long-term maintenance of stable mating properties, IT7-level shaft and hole mating surface , High precision gear surface, important parts subject to variable stress, shaft diameter surface matched with E and D class bearings with a diameter of less than 80mm, shaft surface contacting with rubber seals, IT13~IT16 with a size greater than 120mm Measuring surface of hole and shaft gauge |

|

▽9 |

1.6~3.2 |

1) The direction of the machining traces cannot be discerned |

2) Wheel grinding, grinding, grinding, super processing |

3) The surface of important parts subject to variable stress during work. Ensure the fatigue strength, corrosion resistance and durability of the parts, and do not damage the mating surface during work, such as the shaft diameter surface, the airtight surface and the supporting surface, and the conical centering surface. IT5, IT6 level mating surface, surface of high-precision gear, shaft diameter surface matched with G-level rolling bearing, IT7~IT9 level hole with size greater than 315mm and shaft gauge level IT10~IT12 hole with size greater than 120~315mm Measuring surface of shaft gauge, etc. |

|

▽10 |

0.8~1.6 |

1) Dark glossy surface |

2) Super processing |

3) The surface of important parts that are subjected to large variable stress during work. Ensure precise centering of the cone surface. Hole surface for hydraulic transmission. The inner surface of the cylinder liner, the outer surface of the piston pin, the instrument guide surface, and the valve working surface. IT10~IT12 grade hole and shaft gauge measuring surface with size less than 120mm |

|

▽11 |

0.4~0.8 |

|||

|

▽12 |

0.2~0.4 |

|||

|

▽13 |

0.1~0.2 |

|||

|

▽14 |

<0.1 |