What was Cast Iron Used for in Ancient China

In its long history, human beings have known nature, transformed nature, and invented many technologies. Some technologies, with their rich scientificity, engineering rationality, and wide application range, have been passed down to today since their birth thousands of years ago, and still radiating new vitality. Casting technology is such a technology. Today, let us take a peek at a brief history of casting technology.

-

The arise of casting technology

Inferred from the artifacts found in archaeology, casting technology was mastered by humans after inventing pottery. But with the continuous improvement of understanding, mankind has invented many new casting methods. Therefore, casting technology is both an old and new technology. It is brand new because of the emergence of new casting methods, new casting alloys and new casting equipment. For example, ancient Rome used lead to cast water pipes. And then bronze castings appeared, such as bronze daily utensils and weapons, in China during the Shang and Zhou Dynasties. Then came cast copper, cast gold, cast silver and other different materials.

After mankind invented aluminum, cast aluminum products have become an important category in daily appliances. Such as cast aluminum pot. And the heat sink of the computer we use now, with aluminum block, uses pressure casting method.

In addition, modern foundry factories have introduced computers into the foundry industry for process-aided design. At the same time, manipulators and robots have also been used in foundry. The modern shell manufacturing line can make thousands of casting molds easily and quickly, and then pour into the casting liquid to produce the finished product. Compared with the ancient manual operation, the speed is thousands of times faster.

-

Casting technology with 5,000 years history.

Casting technology can be traced back the late Neolithic period in China, which is more than 5,000 years ago. At that time, the matriarchal clan society developed further. In addition to the Yangshao culture in the middle reaches of the Yellow River, there were also Majiayao culture in the upper reaches of the Yellow River, Dawenkou culture in the lower reaches of the Yellow River, and Daxi culture and Qingliangang culture in the middle and lower reaches of the Yangtze River, all reached a prosperous period.

Many castings have been discovered in these areas mentioned above. Bronze knives dating back nearly 5,000 years at Majiayao, Gansu. Red copper knives and copper cones datingback more than 4,000 years at the Huangniangniangtai site in Wuwei, Gansu. And zinc-containing brass cone of about 4000 years at Jiao County, Shandong. Therefore, Chinese casting technology originated from the late Neolithic period more than 5,000 years ago. The 5,000-year history of casting development in China is an important part of the history of Chinese civilization.

-

During the Shang and Zhou Dynasties, China’s casting technology was relatively mature.

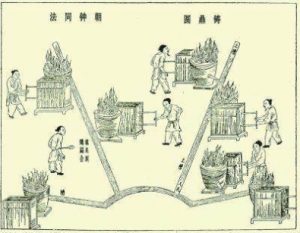

At this time, the production of bronze castings had a certain scale, and the technology also had its own characteristics. It was an important stage in the development of China’s foundry technology. During the Shang and Zhou Dynasties, stone mould changed to pottery mould. The pottery mould is made with sand-containing clay or clay and sand, and then baked. The baking temperature of the early pottery mould is low, about 700~800℃.

According to the analysis of the unearthed pottery mould, the early ones used single material, from the late Shang Dynasty to the early Western Zhou Dynasty. The outer mould of larger castings used fabrics and backing materials, while the inner mould used large amount of sand. And the particle size of the sand is relatively coarse, or add a certain amount of organic matter and clinker to increase air permeability.

The process of making pottery mould is generally to make a clay mold first, and then use the clay mold to make the outer mould. After the outer mould is dry, repair it, and then write a chiseled inscription on the outer mould. Then make the inner mould, which matches the outer mould. Thus the gate is made, and it can be poured. With the need for large-scale casting, such as casting large amounts of copper coins, craftsmen invented metal molds. The service life of the metal mould is much longer than that of the clay mould. And the accuracy is also improved.

-

Development of casting technology in ancient China

With the development of casting technology in ancient China, countless skilled craftsmen have devoted their efforts to countless casting masterpieces. The technology has been handed down to this day. This reflects the excellence of casting technology. In the vast expanse of casting products and exquisite casting skills, a few representative castings and techniques can be cited to give a glimpse of the great achievements of ancient Chinese casting technology.

When it comes to giant castings, we have to mention the important ones in Chinese history.

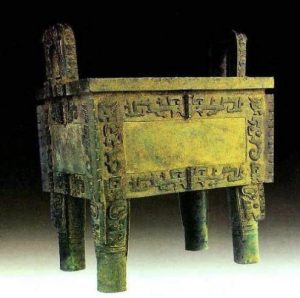

- The 875-kilogram “Simuwu Great Tripod” is China’s biggest piece of bronze ware during the Yin and Shang era.

- The 62-ton “Samantabhadra Riding Elephant” in the Wannian Temple in Mount Emei, Sichuan during the Northern Song Dynasty.

- The unparalleled 46-ton “Yongle Big Bell” duringthe Yongle period of the Ming Dynasty

- The 40-ton “Cangzhou Iron Lion” during the Five Dynasties and the Song Dynasty Jiayou period,

- The 53-ton and 22 meters high “Dangyang Tower”.

- The famous “Qinling Bronze Chariots and Horses”during the Qin Dynasty,

- The “Thousand-Hand Kwan-yin” statue in the Longxing Temple of Zhengding, Hebei during the Northern Song Dynasty,

- The “Iron Cow and Man” in Puzhou Ferry, Yongji, Shanxi.

-

Precision castings

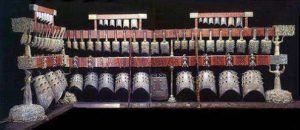

Ancient Chinese precision castings are represented by the “Zunpan” of Zenghouyi in Suixian County, Hubei during the Warring States Period. The technical difficulty is very high even when measured by modern technology. Another example is the “gilding palace lantern” of the Western Han Dynasty,and the Qianlong dynasty. And the “Minghun Instrument”, “abridged armilla” and “Qianlong Colock” as well. All above mentioned are prestigious precision castings cast by the lost wax method. A set of Zenghouyi chimes unearthed in Suixian County, Hubei Province, is known as a world miracle. A full set of 64 pieces, with a total weight of more than 5 tons, this set of chimes is not only beautiful in shape, but also accurate in pitch, which can play very beautiful music. This also shows the ancient superb music theory and casting technology.

There are many special casting techniques in ancient China. For example, the “translucent mirror” cast in the Western Han Dynasty, and the bronze spray fish wash, which are all very magical. There are also many things that are proud of today, such as the surface gilding technology of copper castings, the anti-rust method of bronze swords, lost wax precision casting, malleable cast iron technology, and so on. The foundry industry in ancient China is an important pillar industry of a five-thousand-year civilized society. It has made important contributions to the development of Chinese society and also contributed to the world’s civilization and technological progress.

Yide casting is a leading casting foundry in China, with 27 years’ experience, produces top quantity iron castings. If you are interested in our casting fitting, please send us a drawing file, and feel free to get a quiet quote.