Advantages and Disadvantages of Stainless Steel Casting Process

Advantages and disadvantages of stainless steel casting process

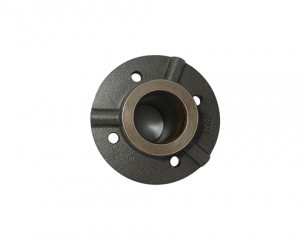

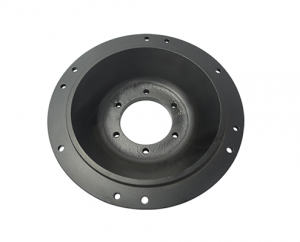

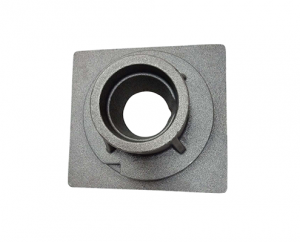

Everyone in the casting industry knows a fact. That is the mechanical properties of stainless steel casting are higher than that of cast iron, but its casting performance is worse than that of cast iron. Stainless steel casting belongs to investment or precision casting, with relatively high melting point. The molten steel is easily oxidized, due to poor fluidity and large shrinkage rate. From a practical perspective, stainless steel casting is suitable for casting of various types and alloys.

Advantages and disadvantages of the stainless steel casting process are as below:

First, due to the poor liquidity of the molten steel, the wall thickness of the steel castings should not be less than 8 mm, in order to prevent the cold shut and misrun. The structure of the pouring system strives to be simple, and the sectional dimension is larger than that of cast iron. Adopt dry casting or hot casting, and the casting temperature should be appropriately increased to 1520-1600 ℃. The fluidity can be improved since the casting temperature is high with large superheat, thus the liquid stays for a long time.

However, if the pouring temperature is too high, it will cause defects such as coarse grains, hot cracks, pores and sand burning. Therefore, the casting temperature of small, thin-walled and complex casting should be at the melting point +150 ℃; and of large, thick-walled casting +100 ℃.

We must take these measures to prevent the occurrence of shrinkage holes and cracks in stainless steel castings. 1. Making the wall thickness uniform, and avoid sharp and right angle structures, 2. Adding sawdust to sand mold, and coke to sand core. 3. Adopting hollow sand core and oil sand core to change the deformability and permeability of the sand mold and core.